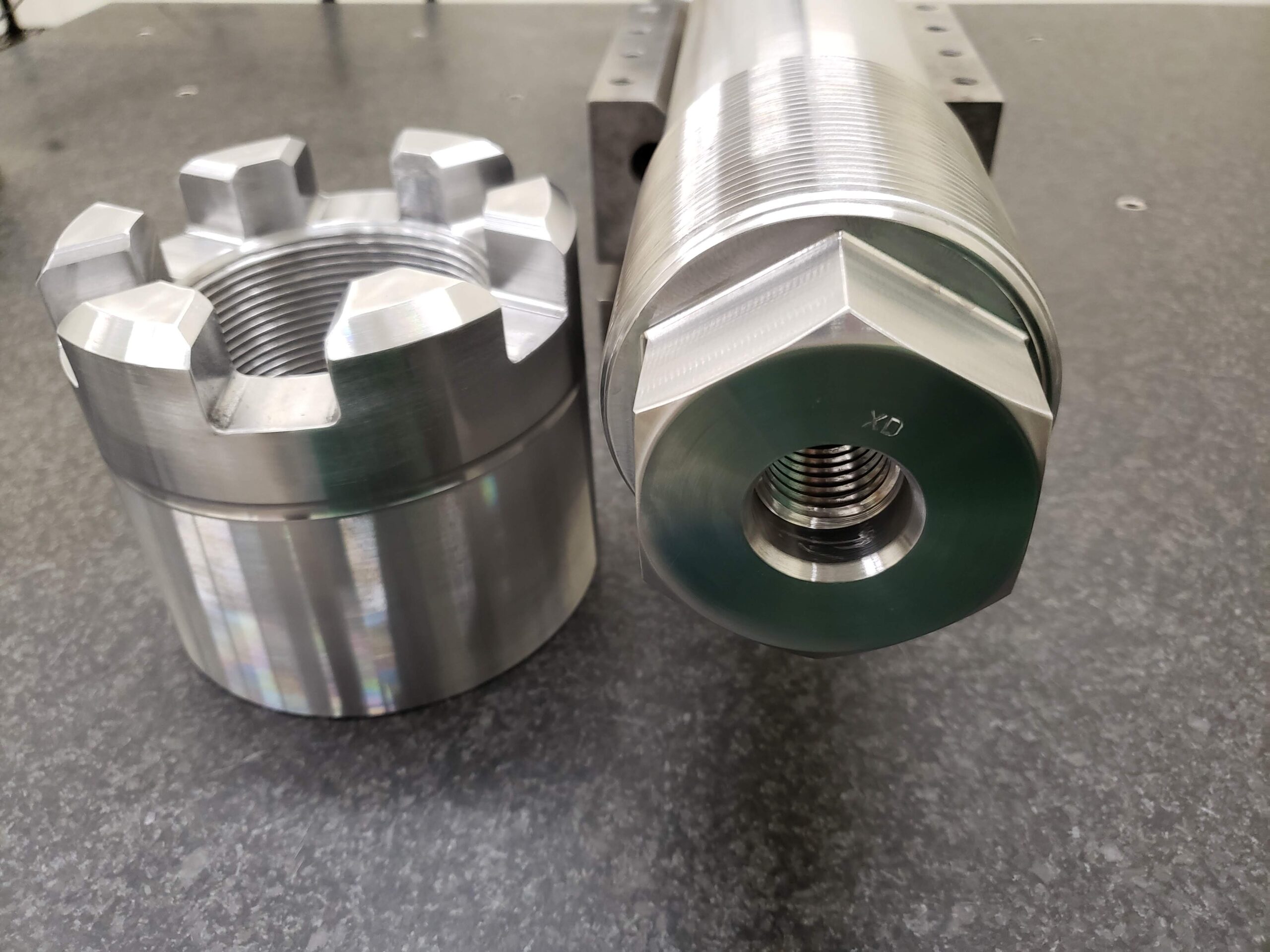

Part Manufacturing

Orbital Energy Services has developed advanced manufacturing processes at our ISO 9001:2015 certified facility to increase durability and prolong component life. Our 100% guaranteed aftermarket parts have saved customers substantial amounts of money – money which translates immediately to the bottom line in the form of reduced operating and/or capital expenses. In addition, Orbital Energy Services has in-house gas nitriding capability, saving our customers valuable time with our ability to schedule nitriding runs any day of the week as needed.

Please visit our website or call us to learn more.