Has your steam turbine outage been postponed?

Many turbine outages this spring have been postponed, and we have a solution to provide peace of mind and mitigate the risk of postponed maintenance.

Your turbine may now be at the point where damage to the internal components could accelerate during this extra runtime. Or perhaps the turbine is operating optimally and the postponed outage was intended to satisfy time-based maintenance requirements. Regardless of how your turbine was operating prior to the postponed inspection, a Running Condition Assessment can provide you (or your insurance company) with the peace of mind that the unit is not nearing a failure point, and provide you with the information needed to properly re-schedule your future outage date.

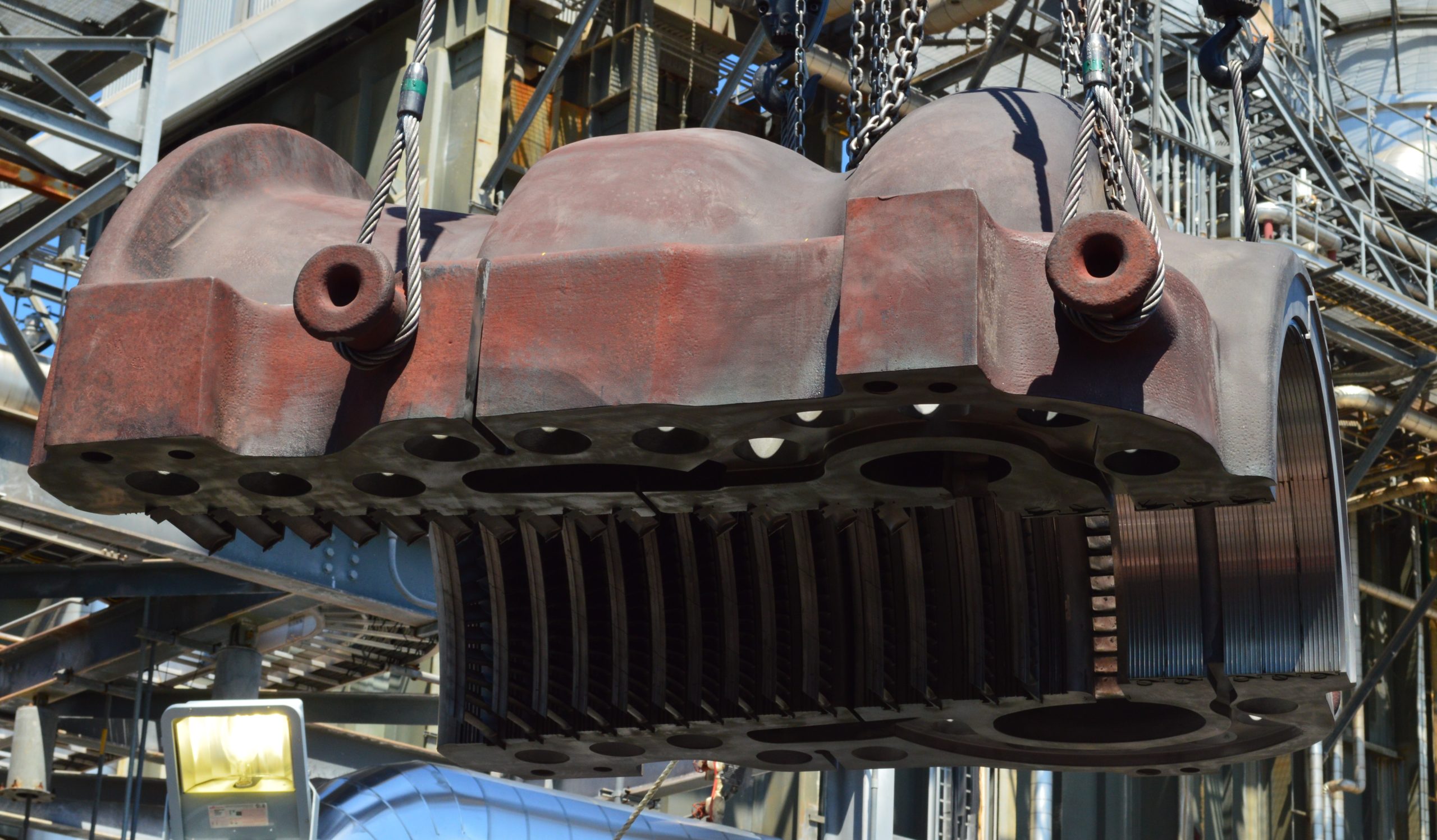

A Running Condition Assessment allows you to assess the health of your turbine generator while the unit is in operation.

This assessment typically includes one specialized technician and equipment at your facility for 3 – 5 days, minimizing the people and time on-site as compared to a standard turbine inspection.

After completion of the Running Condition Assessment you will receive a detailed report on the current condition of your turbine, providing you with vital information for future decision-making.

To learn more about our Running Condition Assessment program, CLICK HERE.

To request a quote and check availability for a Running Condition Assessment, CLICK HERE.

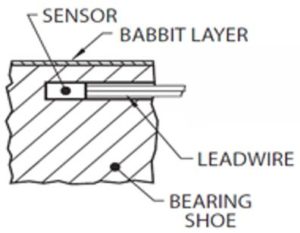

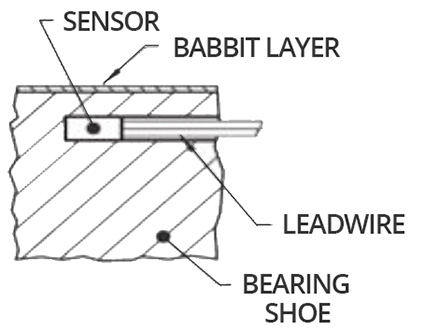

Directly measuring bearing metal temperature is the most effective way to really determine if a bearing is running hot. Bearing oil drain temperatures are still being utilized on older machines. By the time the bearing oil drain temperature has increased, the bearing may have already been compromised (wiped). PSG recommends that these older machines should have temperature probes (thermocouples or RTD’s) installed in the bearing Babbitt to properly monitor performance. A two-level alarm is recommended (not automatic trip). The first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should closely monitor bearing temperature after the first alarm sounds. If the temperature rises abruptly and unexpectedly, the bearing may have been compromised and immediate action needs to be taken. Gradual temperature changes which trigger the alarm may be the result of other factors but are still a concern and should be thoroughly investigated. The second alarm should be set at the maximum operating temperature of the bearing material. Operators should manually trip the unit in a controlled manner as soon as possible after this second alarm sounds and determine the cause. The critical temperatures for each of the two levels can be supplied by the manufacturer or recommended by PSG for your individual unit configuration. Different temperature ranges are recommended for Tilt Pad, Elliptical, Short Elliptical and Thrust bearings. Measuring drain oil temperature is too slow and too imprecise to effectively minimize your overall cost of maintenance. Retrofit your machine and save your bottom line.

Directly measuring bearing metal temperature is the most effective way to really determine if a bearing is running hot. Bearing oil drain temperatures are still being utilized on older machines. By the time the bearing oil drain temperature has increased, the bearing may have already been compromised (wiped). PSG recommends that these older machines should have temperature probes (thermocouples or RTD’s) installed in the bearing Babbitt to properly monitor performance. A two-level alarm is recommended (not automatic trip). The first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should closely monitor bearing temperature after the first alarm sounds. If the temperature rises abruptly and unexpectedly, the bearing may have been compromised and immediate action needs to be taken. Gradual temperature changes which trigger the alarm may be the result of other factors but are still a concern and should be thoroughly investigated. The second alarm should be set at the maximum operating temperature of the bearing material. Operators should manually trip the unit in a controlled manner as soon as possible after this second alarm sounds and determine the cause. The critical temperatures for each of the two levels can be supplied by the manufacturer or recommended by PSG for your individual unit configuration. Different temperature ranges are recommended for Tilt Pad, Elliptical, Short Elliptical and Thrust bearings. Measuring drain oil temperature is too slow and too imprecise to effectively minimize your overall cost of maintenance. Retrofit your machine and save your bottom line. Free and emulsified water are the two most harmful conditions in a lubricating system. The incompressibility of water overrides the hydrodynamic oil film that protects bearings, leading to excessive wear. As little as one percent water in oil can reduce the life expectancy of a journal bearing by as much as 90 percent.

Free and emulsified water are the two most harmful conditions in a lubricating system. The incompressibility of water overrides the hydrodynamic oil film that protects bearings, leading to excessive wear. As little as one percent water in oil can reduce the life expectancy of a journal bearing by as much as 90 percent. A two-level alarm is recommended (not automatic trip). Consequently, the first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should also closely monitor bearing temperature after the first alarm sounds.

A two-level alarm is recommended (not automatic trip). Consequently, the first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should also closely monitor bearing temperature after the first alarm sounds. As the rotor slows down, the oil needs to be more viscous to repel the force towards the bearing.

As the rotor slows down, the oil needs to be more viscous to repel the force towards the bearing.