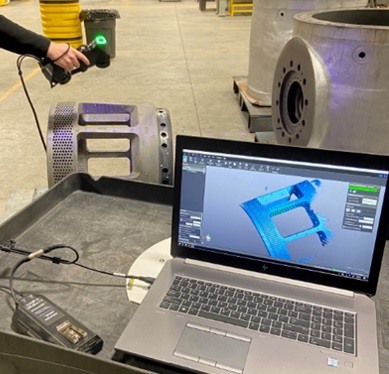

3D Component Scanning

It’s that time of year again! When turbines are running throughout the summer season it’s a good time to scan any common parts that you may need to order again in the future. With our portable metrology-grade 3D scanning equipment, we are able to scan components within extreme accuracy. You can ship your components to our shop, or we can bring the experienced technicians and scanning equipment to your facility and analyze the components right there at your site. If you have any component engineering needs please give us a call. We’d love the opportunity to help in any way we can. CLICK HERE for our phone and email contact information.