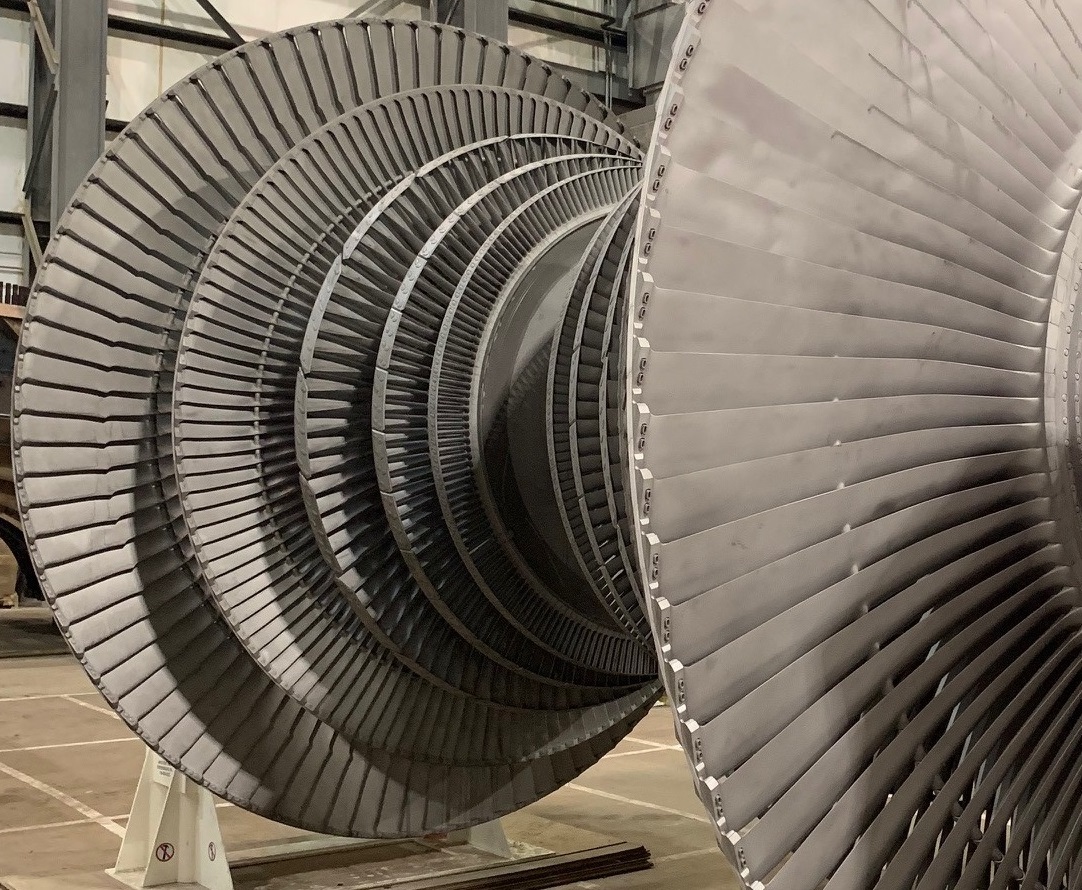

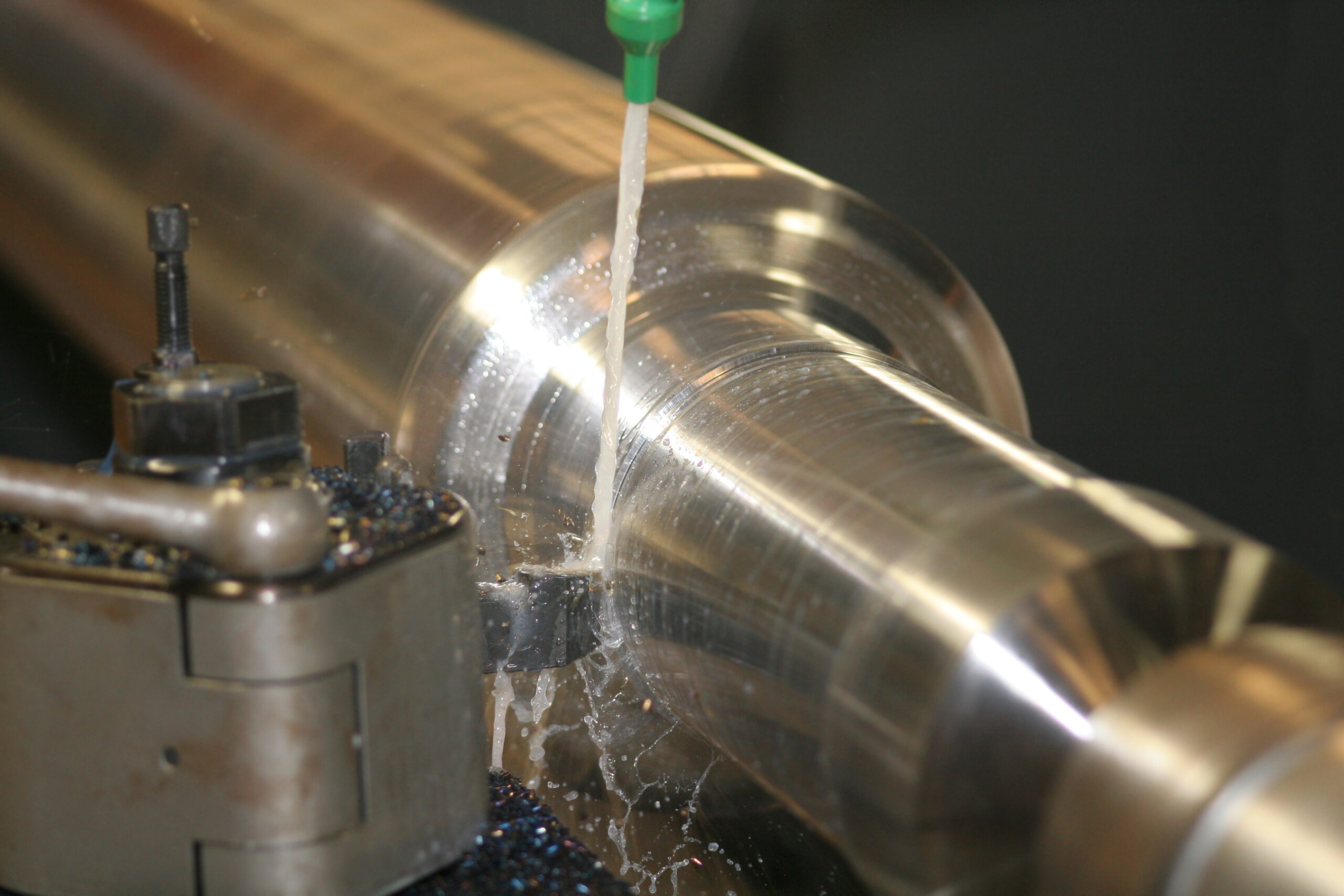

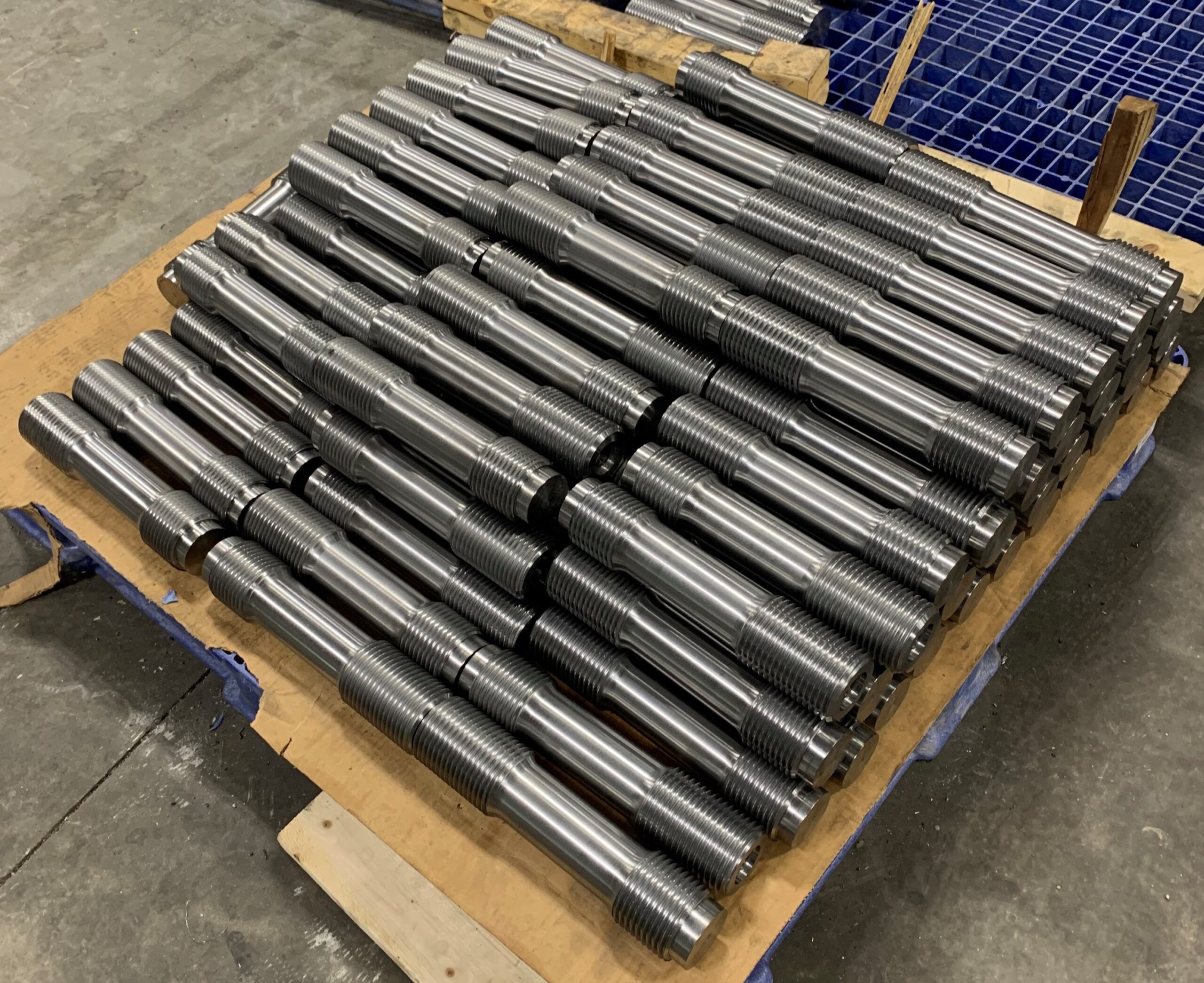

PSG mobilized tooling, supervision, and craft labor to a paper mill located on the East Coast, USA to perform a scheduled major inspection on their GE steam turbine. The scope of work including removing the steam turbine rotor and steam path components for inspection. The steam turbine rotor and internal components were shipped off site for sand blasting, nondestructive examination (NDE), and inspection. The T-1, T-2, T-3, and T-4 bearings were all sent out for repair. The #1 inboard, #2 inboard, and #3 outboard bearing oil deflectors were sent out for refurbishment, inspections found that all three seals had excessive clearance.

Auxiliary work included: inspecting the NRV valve, 1200# MSV, 850# MSCV, all three lube oil pumps, V-1 upper, V-1 lower, and V-2 valve racks and operating cylinders, the lube oil coolers and generator coolers were shipped out for cleaning and inspections, the lube oil and EHC systems were cleaned utilizing a high velocity oil flush. The generator stator and rotor were inspected and cleaned.

The end result was a successful inspection, with zero safety incidents, and a satisfied customer. If you would like us to quote your next steam turbine major inspection, please click here to submit your request.