AEP Go Forum

Stop by and visit us at the AEP Go Forum!

Stop by and visit us at the AEP Go Forum!

During the most recent outage season, PSG was contracted to perform the in-place restoration of stationary blades on an 800MW Steam Turbine for a large power producer in the United States. The customer was looking for a solution where the blades could be restored without completely disassembling the unit and sending the components to a shop – enabling them to save valuable generation time and significant expense. Our Field Machining Division mobilized our specialized technicians and equipment and began the detailed process of restoring the blades, ultimately returning them to operating specifications.

The customer was extremely pleased with the outcome of the project and commented on the high-quality craftsmanship displayed by our technicians. This is another example of the complicated turbine repairs we can perform on-site, and a testament to the quality of our execution personnel.

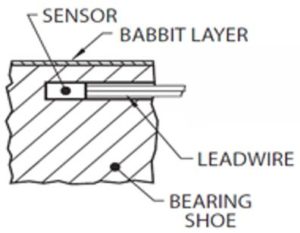

Directly measuring bearing metal temperature is the most effective way to really determine if a bearing is running hot. Bearing oil drain temperatures are still being utilized on older machines. By the time the bearing oil drain temperature has increased, the bearing may have already been compromised (wiped). PSG recommends that these older machines should have temperature probes (thermocouples or RTD’s) installed in the bearing Babbitt to properly monitor performance. A two-level alarm is recommended (not automatic trip). The first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should closely monitor bearing temperature after the first alarm sounds. If the temperature rises abruptly and unexpectedly, the bearing may have been compromised and immediate action needs to be taken. Gradual temperature changes which trigger the alarm may be the result of other factors but are still a concern and should be thoroughly investigated. The second alarm should be set at the maximum operating temperature of the bearing material. Operators should manually trip the unit in a controlled manner as soon as possible after this second alarm sounds and determine the cause. The critical temperatures for each of the two levels can be supplied by the manufacturer or recommended by PSG for your individual unit configuration. Different temperature ranges are recommended for Tilt Pad, Elliptical, Short Elliptical and Thrust bearings. Measuring drain oil temperature is too slow and too imprecise to effectively minimize your overall cost of maintenance. Retrofit your machine and save your bottom line.

Directly measuring bearing metal temperature is the most effective way to really determine if a bearing is running hot. Bearing oil drain temperatures are still being utilized on older machines. By the time the bearing oil drain temperature has increased, the bearing may have already been compromised (wiped). PSG recommends that these older machines should have temperature probes (thermocouples or RTD’s) installed in the bearing Babbitt to properly monitor performance. A two-level alarm is recommended (not automatic trip). The first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should closely monitor bearing temperature after the first alarm sounds. If the temperature rises abruptly and unexpectedly, the bearing may have been compromised and immediate action needs to be taken. Gradual temperature changes which trigger the alarm may be the result of other factors but are still a concern and should be thoroughly investigated. The second alarm should be set at the maximum operating temperature of the bearing material. Operators should manually trip the unit in a controlled manner as soon as possible after this second alarm sounds and determine the cause. The critical temperatures for each of the two levels can be supplied by the manufacturer or recommended by PSG for your individual unit configuration. Different temperature ranges are recommended for Tilt Pad, Elliptical, Short Elliptical and Thrust bearings. Measuring drain oil temperature is too slow and too imprecise to effectively minimize your overall cost of maintenance. Retrofit your machine and save your bottom line.

We are in the process of installing new spill strips for an industrial GE Steam Turbine. Very nice work by our Steam Path Repair facility in Pevely, Missouri.

Power Services Group brings you a wide range of services specific to industries like yours, offering exceptional value and responsiveness. We can hit the ground running and deliver results so you can have peace of mind and your equipment is always available.

125 SW 3rd Place, Suite 300

Cape Coral, FL 33991

Phone: (800) 226-7557