New Years Weekend!

Mr. Turbine says some astronauts wanted to have a New Year’s party on the moon, but they didn’t planet in time.

Mr. Turbine wishes you a Happy New Year!

Mr. Turbine says some astronauts wanted to have a New Year’s party on the moon, but they didn’t planet in time.

Mr. Turbine wishes you a Happy New Year!

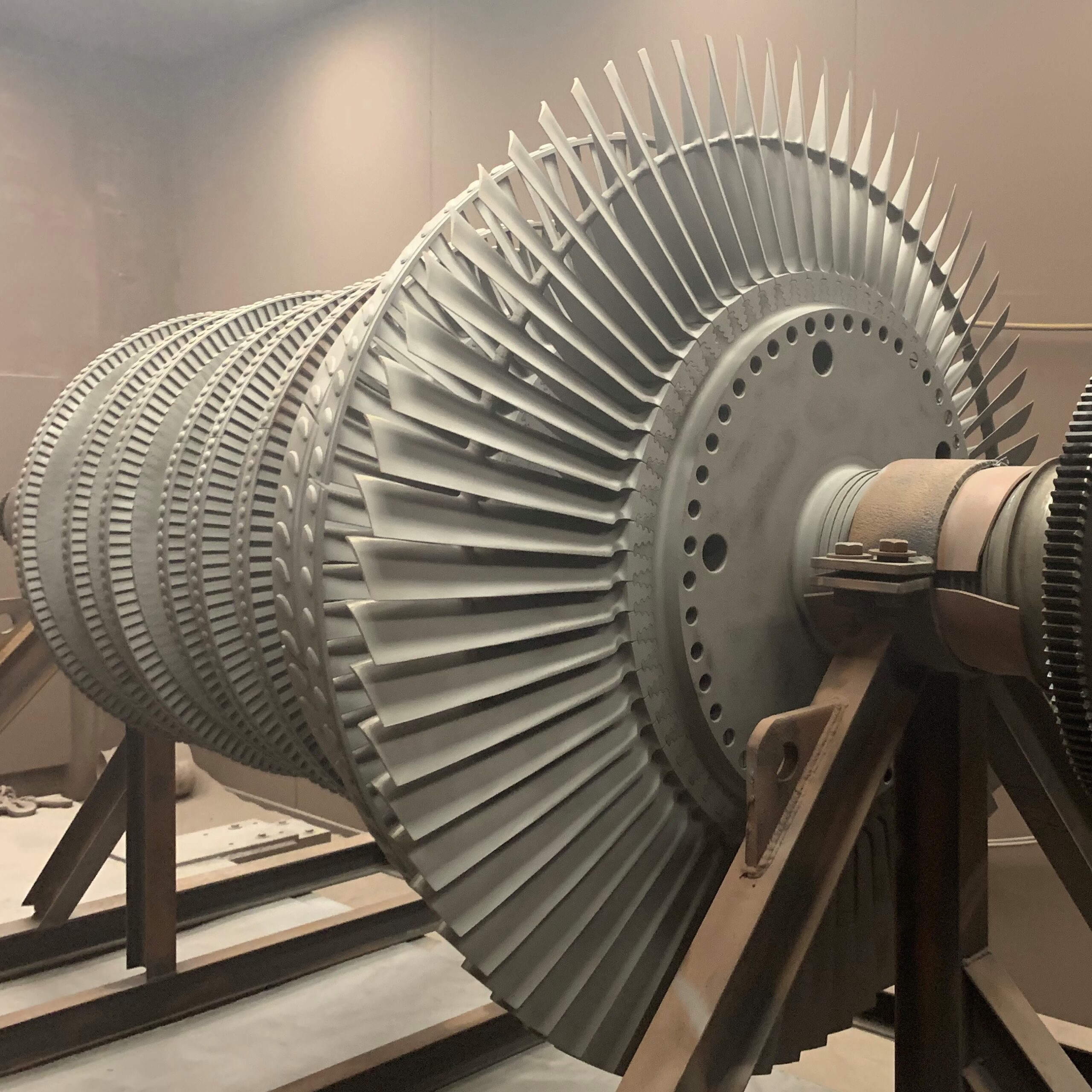

Turbine component life management is very important to the overall reliability and availability of your turbine. Preventative maintenance and performing quality repairs during the normal lifetime of your steam turbine components will allow your components to be in the best condition possible when evaluating the future operating lifespan. If you are looking for quality steam turbine component inspections or repairs to be performed during your next turbine outage please contact us today.

Power Services Group provides turnkey outage services for fossil and nuclear steam turbines ranging from 1MW to 1,300MW for all major OEMs. Our flexible and cost-effective steam turbine solutions can help operators reduce equipment downtime and extend the life of steam turbine components. Visit our website to learn more!

Diaphragm Repairs, Blade/Bucket Repairs, Journal Machining, Valve Repairs, Joint Machining, Destructive Stud Removal and Hole Restoration – any potential repair that your steam turbine may require… Contact us today to discuss the evaluation of your steam turbine components. We will provide a thorough recommendation on what repairs should be executed during your outage to maximize your turbine’s efficiency and/or reliability and discuss what repairs can potentially wait until the next Major Inspection.

If you have a tight outage window and require the fastest repair time available, or would simply like competitive pricing for your repairs, we can provide you with options to execute in the most efficient and cost-effective manner.

Sometimes there is more concern for completing a job quickly rather than safely. Take time to do a quality job, safely. All injuries can be avoided. One of the best ways to learn how to work safely is to learn from risks others have taken that lead to injuries. By avoiding unsafe acts and practicing common sense, safe job practices will become routine, with less chance for accidents. To learn more about safety visit our website.

Mr. Turbine asks What’s the worst thing that can happen on a Friday? Realizing its only Thursday!

Steam turbines can reliably run for 30 years or more. However, everything wears down over time, and eventually fits, finishes, and tolerances will become unacceptable. For instance, the rabbet fit on the coupling faces of a three-bearing machine will eventually require repair. This issue may cause misalignment, abnormal vibrations, and stresses to the rotors. To learn more about our services visit our website for more information.

OSHA, the Occupational Safety and Health Administration, was created in 1970 to prevent dangerous working conditions. They require workers to complete safety compliance training focused on eliminating or diminishing occupational injury, illness, and death. At Power Services Group, we prioritize safety for all employees to ensure safe jobsite practices.

To learn more about jobsite safety please visit our website.

Mr. Turbine says Winter is here, weather you like it or not and the turbine experts are still here for all your turbine needs!

Power Services Group brings you a wide range of services specific to industries like yours, offering exceptional value and responsiveness. We can hit the ground running and deliver results so you can have peace of mind and your equipment is always available.

125 SW 3rd Place, Suite 300

Cape Coral, FL 33991

Phone: (800) 226-7557