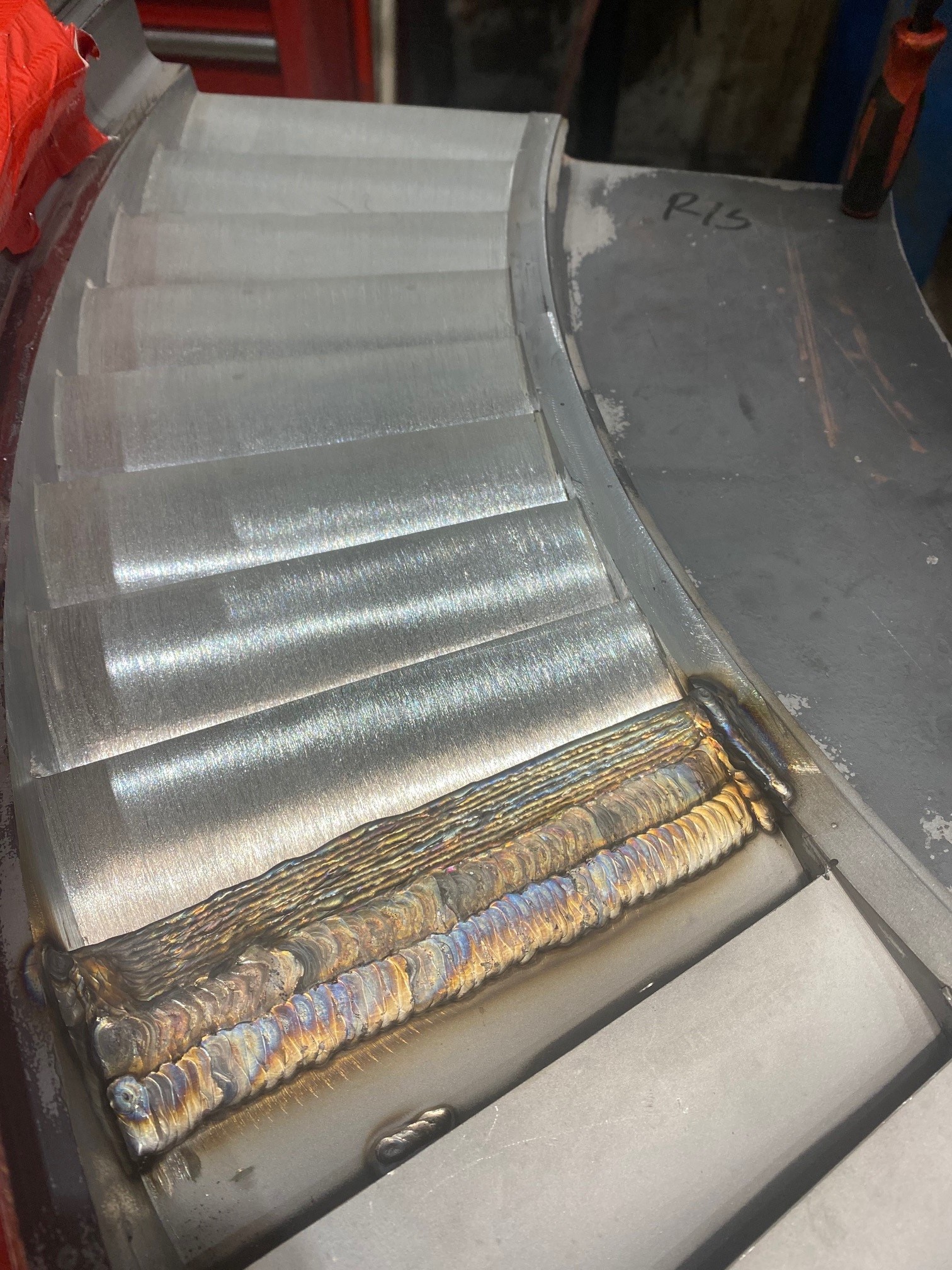

Gas Nitriding of Turbine Components

One of the durability enhancements we offer for turbine components is gas nitriding. Gas nitriding is a surface hardening process, where nitrogen is added to the surface of steel parts using dissociated ammonia as the source. Gas nitriding develops a very hard case in a component at relatively low temperature, without the need for quenching. As a result, a very high strength product with extremely good wear resistance can be produced, with little or no dimensional change. For valve components, these material enhancements translate into increased durability and service life and ultimately, reduced maintenance cost.

Gas nitriding can be a time consuming process, which is why we have the equipment in-house to ensure you receive the quickest turnaround times possible during your turbine outage. If you want to learn more about this and other durability improvements we offer please visit our part manufacturing web page HERE.