Field Machining

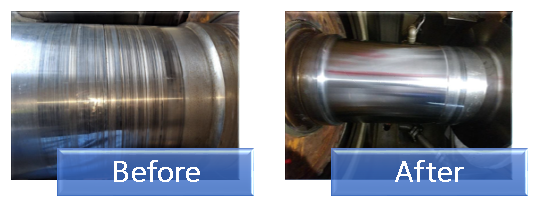

Power Services Group’s On-Site Machining Service provides precision, transportable machine tools, and highly qualified technicians to skillfully perform work at your facility. Our unique on-site shaft machining process requires absolutely no need for shaft rotation. Performed on-site, we have eliminated the issues related to removing and shipping your equipment to a shop: costly mobilizations, exorbitant shipping costs, potential damage during shipment, valuable lay down space, and plant crane and rigging requirements. To learn more about our services visit our website for more information.