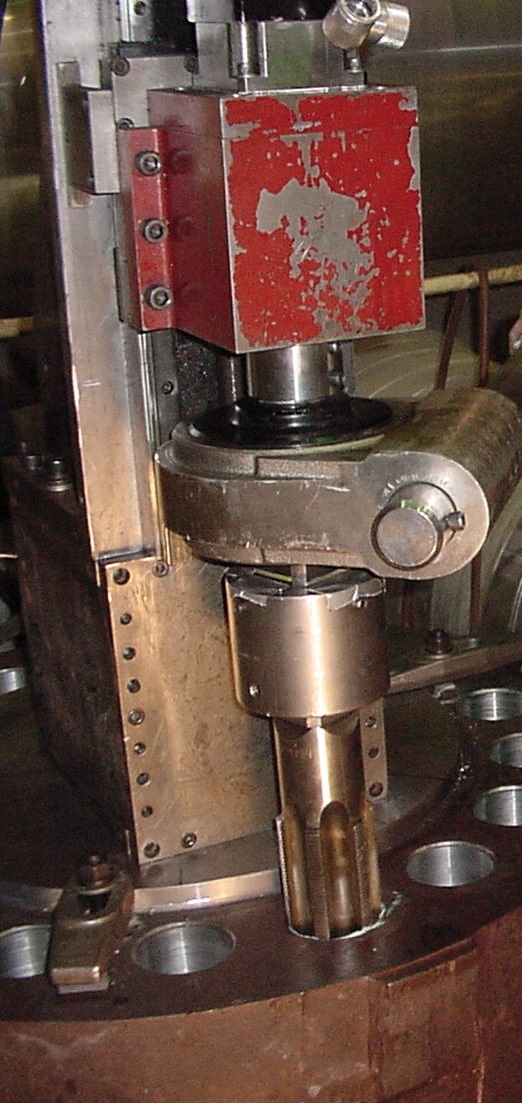

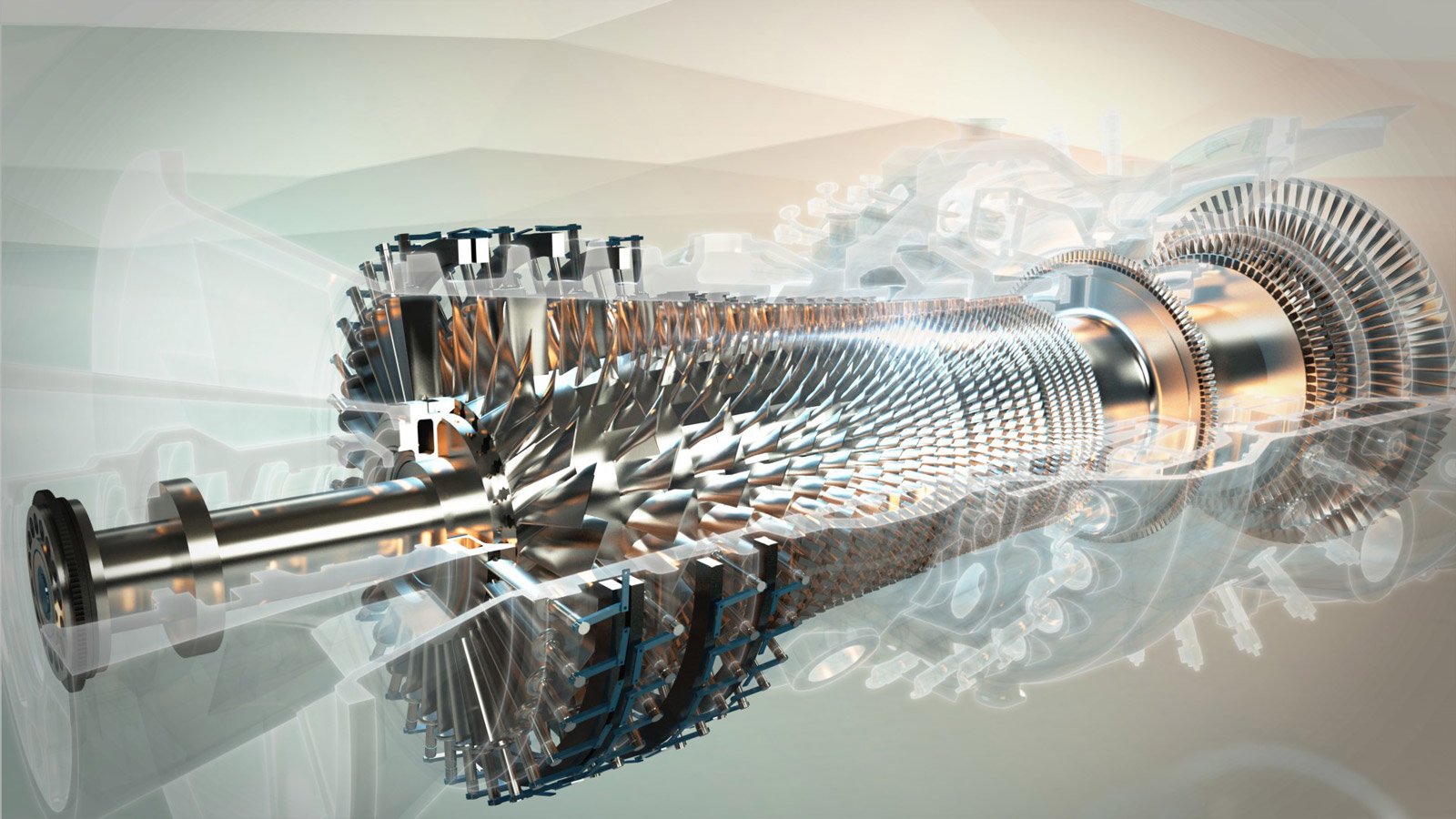

Equipment size or time constraints keeping you from shipping components off-site? On-site machining work can be performed at your facility, almost regardless of size, position, damage, material, etc. If there is enough room for our equipment to be set up, and the work is within the limitations of the portable equipment, then it can be done. Equipment available includes a fully equipped portable machine shop, portable horizontal lathe, and portable vertical turret lathe (VTL), and much more. Once on-site, unloading, and loading of our machining equipment is quick and is typically accomplished with a small forklift. If you would like machining work performed at your site during your next turbine outage please contact us today to confirm the work can be executed with high quality and within your scheduled timeframe.