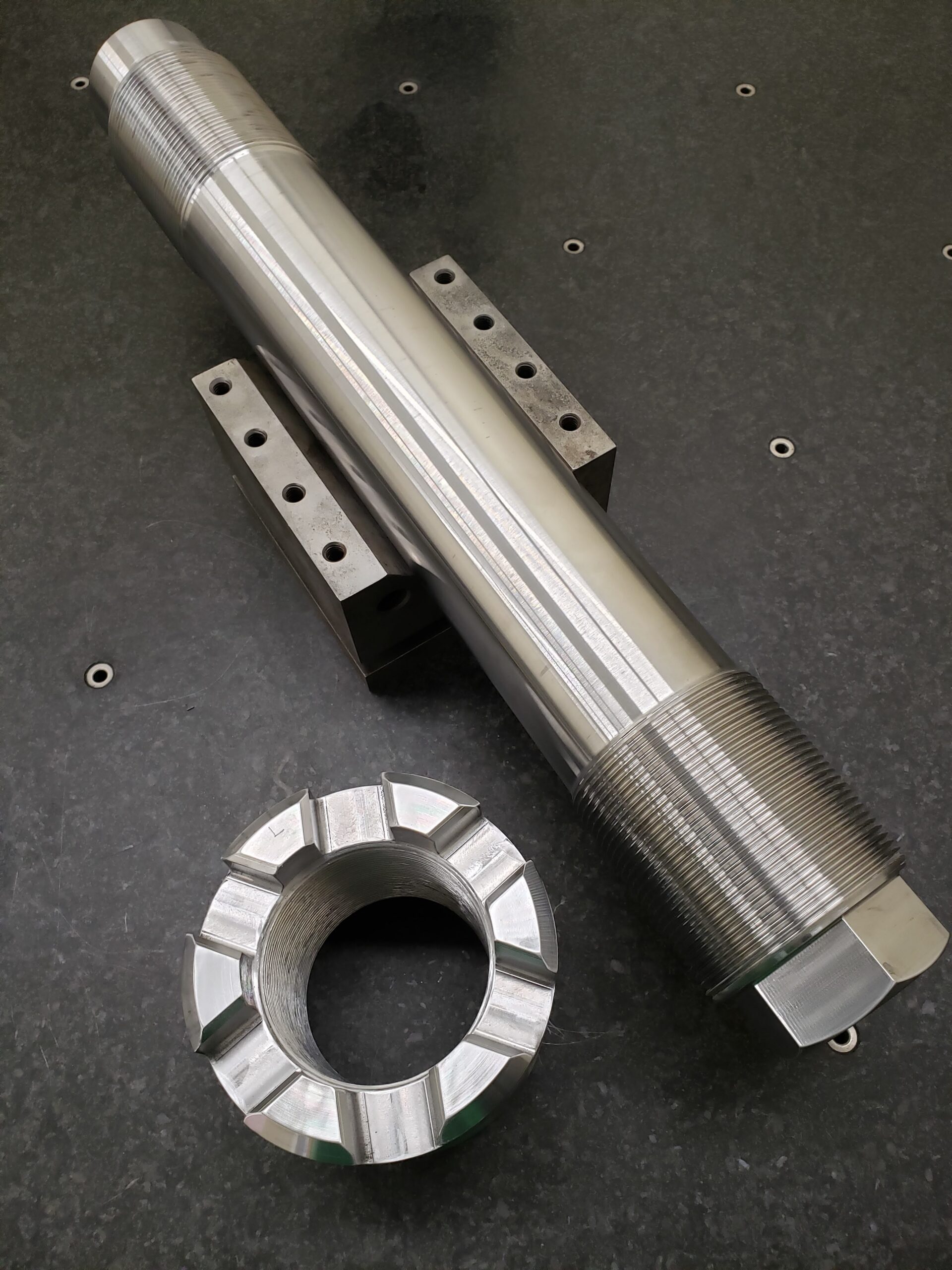

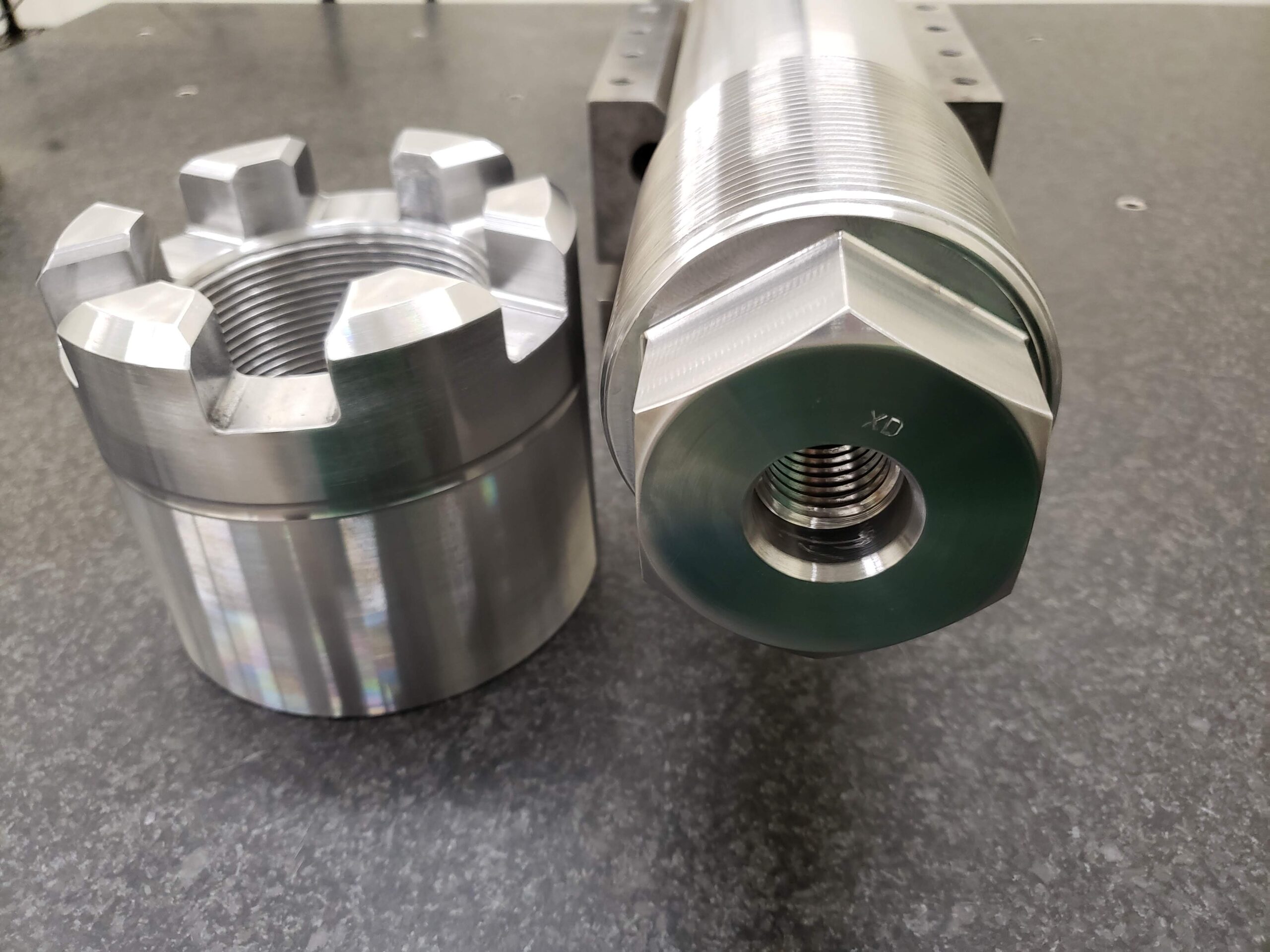

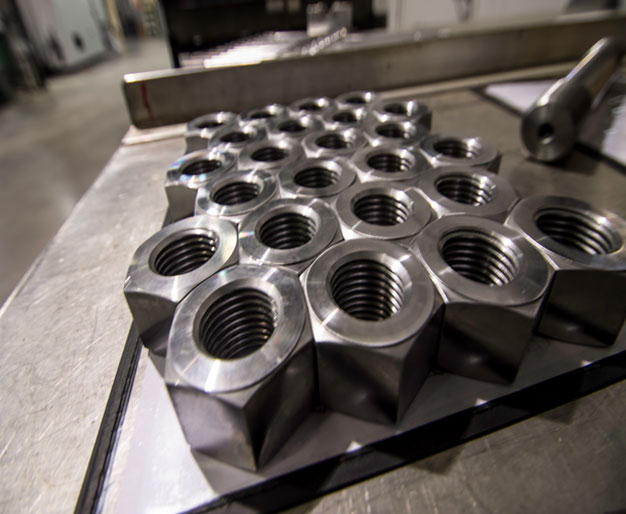

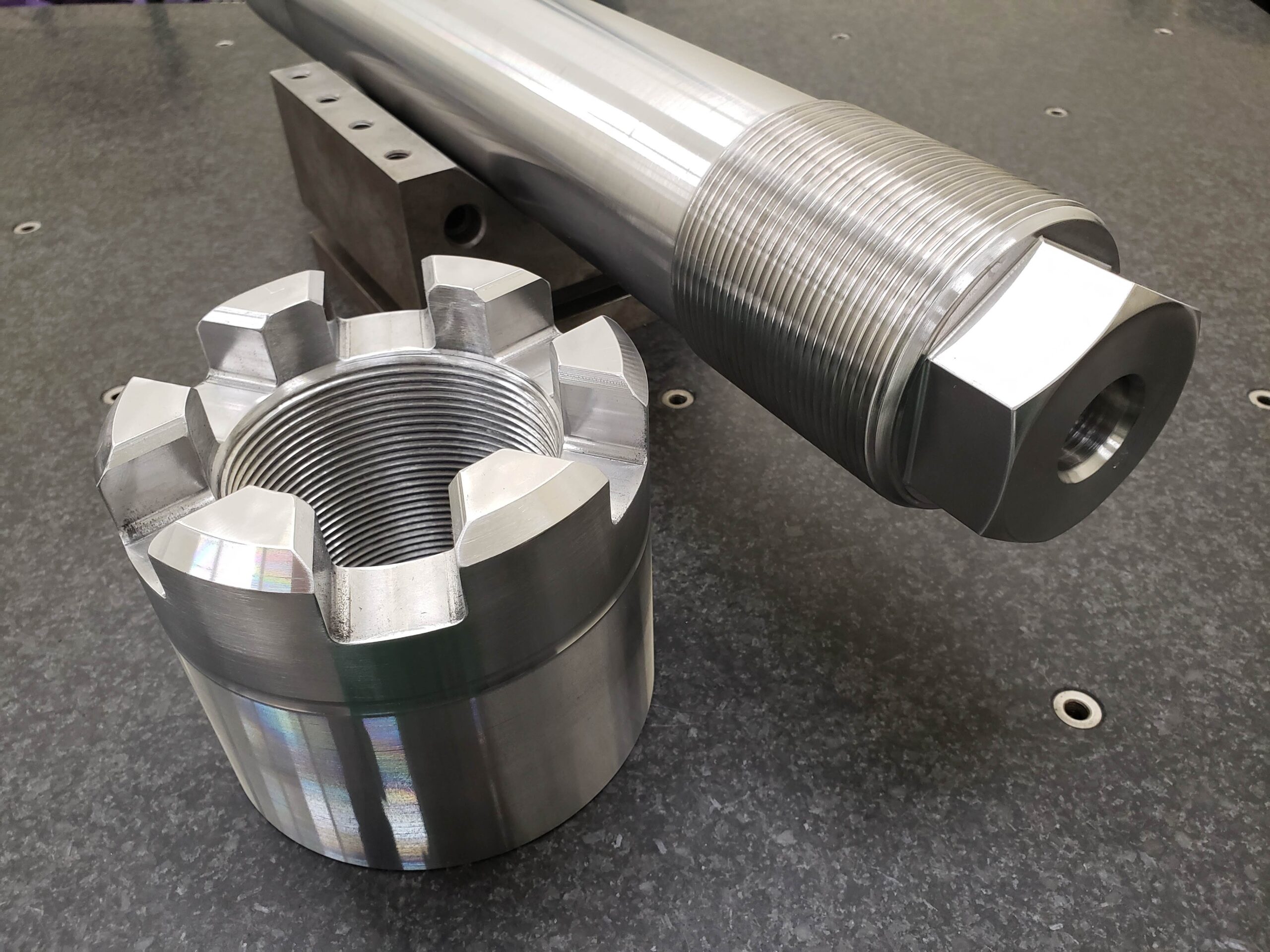

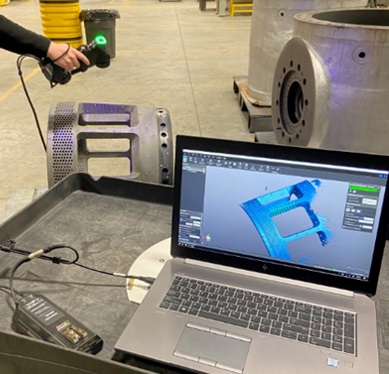

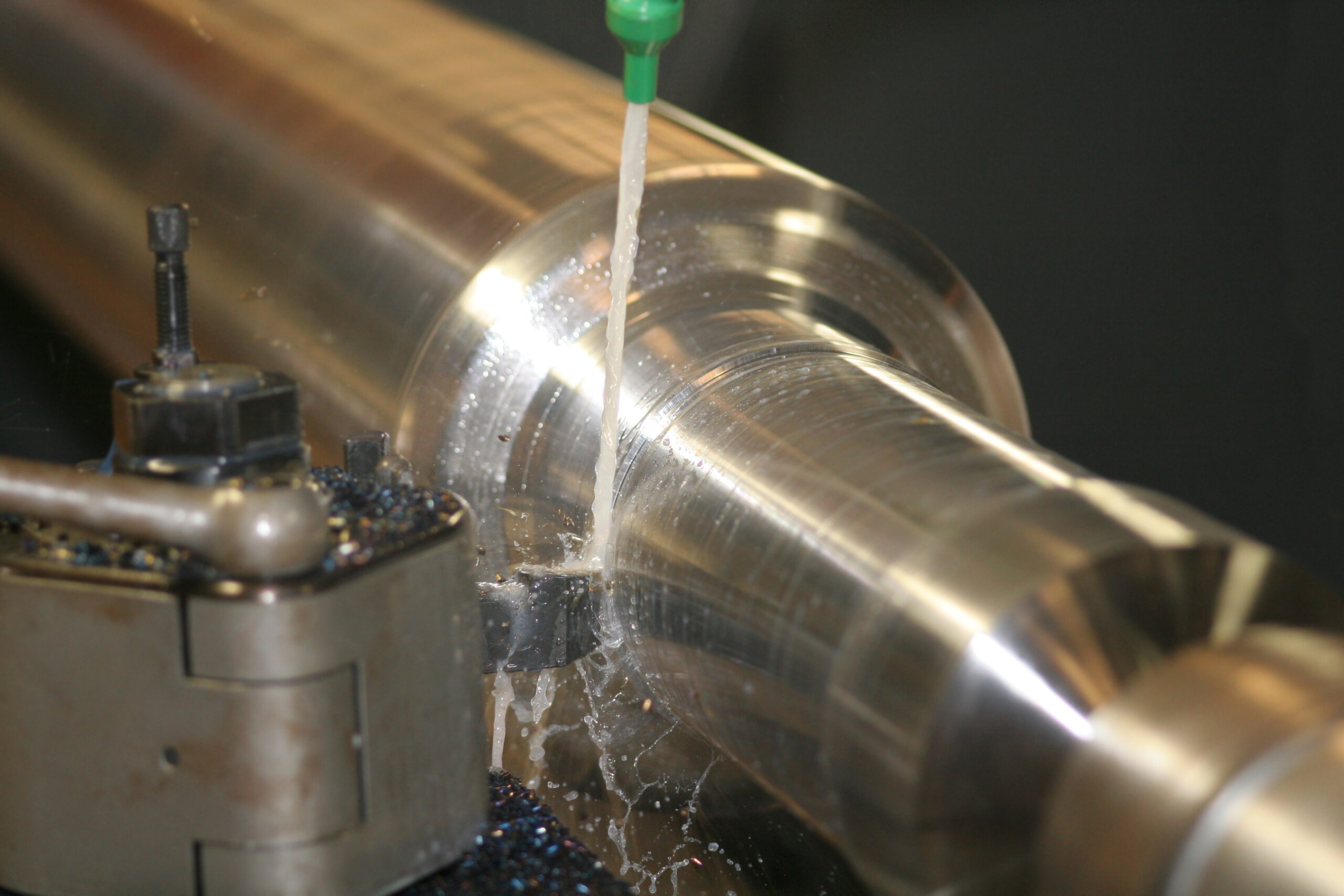

Part Manufacturing

At PSG our specialized manufacturing equipment and skilled technicians create parts with a high level of quality and durability. All manufacturing is completed at our ISO 9001:2015 certified part manufacturing facility in Gainesville, Georgia. Let us increase your margins by replacing your machine’s OEM parts with aftermarket parts manufactured by Orbital Energy Services. Please visit our website or call us to learn more.