Why is a Clean Generator a Happy Generator?

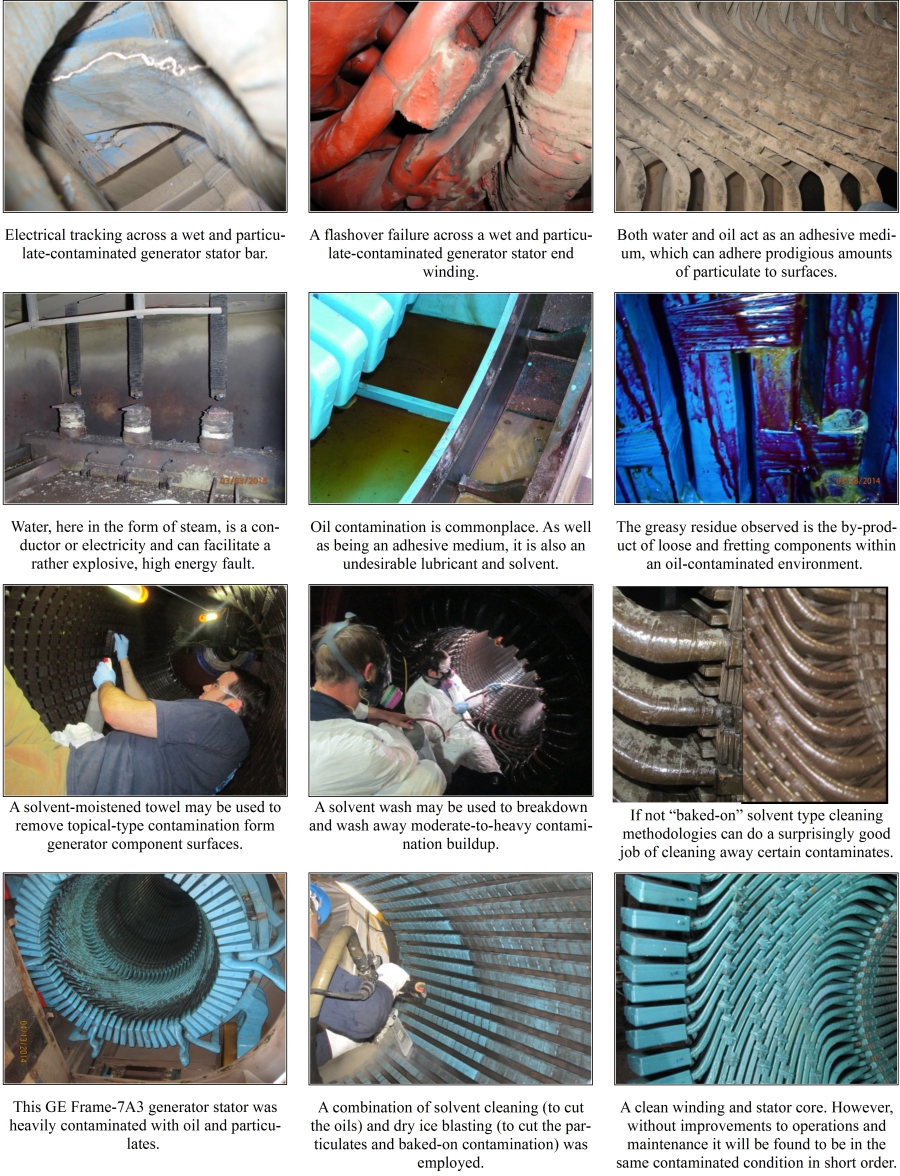

A generator is susceptible to four categories of aging factors which reduce the overall service life of the machine: 1) Mechanical aging; 2) Thermal aging; 3) Electrical aging; 4) Environmental aging. Simply stated, a dirty (contaminated) generator causes environmental aging. A few of the more common contamination elements include oil, water, dirt, dust, carbon, and fly ash. Environmental aging factors will facilitate the other three aging mechanisms as well. Examples: 1) Mechanical aging – the integrity of a stator winding may loosen and degrade as binders in the epoxies and varnishes are broken down by solvents and chemicals. 2) Thermal aging – Insulation systems throughout a generator will break down if contaminates build-up and block-off ventilation passageways such that thermal classification limits are exceeded. 3) Electrical aging – Phase-to-ground and/or phase-to-phase flashovers may occur between two dielectric weak points sufficiently bridged by a conductive coating of contaminates.

A generator is susceptible to four categories of aging factors which reduce the overall service life of the machine: 1) Mechanical aging; 2) Thermal aging; 3) Electrical aging; 4) Environmental aging. Simply stated, a dirty (contaminated) generator causes environmental aging. A few of the more common contamination elements include oil, water, dirt, dust, carbon, and fly ash. Environmental aging factors will facilitate the other three aging mechanisms as well. Examples: 1) Mechanical aging – the integrity of a stator winding may loosen and degrade as binders in the epoxies and varnishes are broken down by solvents and chemicals. 2) Thermal aging – Insulation systems throughout a generator will break down if contaminates build-up and block-off ventilation passageways such that thermal classification limits are exceeded. 3) Electrical aging – Phase-to-ground and/or phase-to-phase flashovers may occur between two dielectric weak points sufficiently bridged by a conductive coating of contaminates.

The two most common and virulent contaminates are water and oil. Each of these two materials act as an adhesive that binds particulates into a buildup across surfaces throughout a generator. This is especially true of air-cooled machines. Also, water is a conductor of electricity. The ramifications of its presence need no explanation.

Oil contamination is undesirable for two additional reasons. First, it is a lubricant. Electrical windings, and in particular stator windings, are held tightly together through a number of frictional forces. Side packing holds the stator windings tightly within the stator slots side-to-side. The wedge system holds the stator windings radially within the same slots. Hundreds of blocks and miles of lacing secure the stator end windings to one another as well as to surge rings and brackets. Oil contamination leaches in between all these components. Its lubricating qualities facilitates looseness and mechanical fretting. Second, oil is a mild solvent. Over time it will break down the organic binders in paints, varnishes, and even modern epoxies. Degradation of these materials reduces the dielectric strength of the ground wall insulation system and accelerates electrical aging. Oil’s solvent and lubrication properties contribute to mechanical aging by impairing the homogeneous and monolithic character of the stator winding. Oil contamination must be eliminated (to the best degree possible) to ensure the long-term serviceability of a generator. More importantly, the source of the leakage must be remediated.

Opinions vary regarding proper cleaning materials and methodologies. However, it should be considered as best practice to define a cleaning protocol based upon: 1) Type of contamination; 2) Degree of contamination; 3) Type of insulation system, and; 4) Condition/disposition of the insulation system. Cleaning may include simple wipe down, solvent spraying, dry ice blasting, dry media blasting (corn cob, walnut shell, etc.), steam cleaning, or some combination. Positives and negatives are associated with each and should be discussed prior to implementation.

Simply stated, a clean generator is a happy generator. A consistently clean generator runs cooler, stays mechanically-robust longer, and is significantly less prone to electrical tracking and flash-over failure. A clean generator demonstrates superior operation and maintenance practices and helps assure quality service life. How clean is your generator?