Inadequate Oil Supply: Measure the Cause, Not the Symptom

This is Part Three of a three part series on steam turbine tips, discussing the challenge of inadequate oil supply.

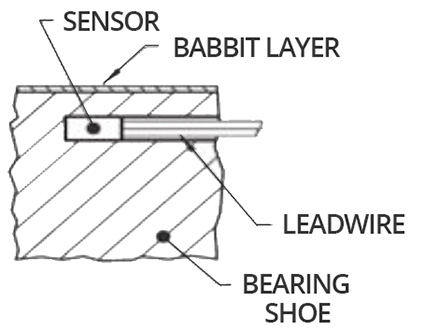

Directly measuring bearing metal temperature is the most effective way to really determine if a bearing is running hot.

Bearing oil drain temperatures are still being utilized on older machines. By the time the bearing oil drain temperature has increased, the bearing may have already been compromised (wiped). PSG recommends that these older machines should have temperature probes (thermocouples or RTD’s) installed in the bearing Babbitt to properly monitor performance.

A two-level alarm is recommended (not automatic trip). Consequently, the first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should also closely monitor bearing temperature after the first alarm sounds.

A two-level alarm is recommended (not automatic trip). Consequently, the first alarm should be set a few degrees above the highest temperature in the recommended normal operating range. Operators should also closely monitor bearing temperature after the first alarm sounds.

Keep in mind that if the temperature rises abruptly and unexpectedly, the bearing may have been compromised and immediate action needs to be taken. Gradual temperature changes which trigger the alarm may be the result of other factors but are still a concern and should be thoroughly investigated.

The second alarm should be set at the maximum operating temperature of the bearing material. Operators should manually trip the unit in a controlled manner as soon as possible after this second alarm sounds and determine the cause.

The critical temperatures for each of the two levels can be supplied by the manufacturer or recommended by PSG for your individual unit configuration. Different temperature ranges are recommended for Tilt Pad, Elliptical, Short Elliptical, and Thrust bearings.

Measuring drain oil temperature is too slow and too imprecise to effectively minimize your overall cost of maintenance. Taking all of this into consideration, the best practice is to retrofit your machine and save your bottom line.

Do you have questions about your steam turbine backup system? Contact PSG today to explore how we can provide support and maintenance options to help you avoid backup system problems.

As the rotor slows down, the oil needs to be more viscous to repel the force towards the bearing.

As the rotor slows down, the oil needs to be more viscous to repel the force towards the bearing. During the first half of 2017, PSG successfully performed a number of maintenance activities at combined cycle power plants with Alstom GT 24 Integrated Cycle System (ICS) turbine-generator equipment. GT24 work executed by the PSG team for multiple customers throughout the continental U.S. and Latin America:

During the first half of 2017, PSG successfully performed a number of maintenance activities at combined cycle power plants with Alstom GT 24 Integrated Cycle System (ICS) turbine-generator equipment. GT24 work executed by the PSG team for multiple customers throughout the continental U.S. and Latin America: Most of these steam turbine failures are caused by an unreliable backup system to maintain oil pressure to the bearings should the primary AC-driven lube oil pumps fail. These AC motors are powered by either the turbine’s output or the grid—causing a failure if the turbine or generator trips—or if there is an external outage.

Most of these steam turbine failures are caused by an unreliable backup system to maintain oil pressure to the bearings should the primary AC-driven lube oil pumps fail. These AC motors are powered by either the turbine’s output or the grid—causing a failure if the turbine or generator trips—or if there is an external outage. Power Services Group recently completed a 500 hour base bolt tensioning project for 122 Siemens 2.3 megawatt wind turbines for a customer in Kansas. Consider Power Services Group for all of your wind turbine bolt tensioning needs.

Power Services Group recently completed a 500 hour base bolt tensioning project for 122 Siemens 2.3 megawatt wind turbines for a customer in Kansas. Consider Power Services Group for all of your wind turbine bolt tensioning needs.