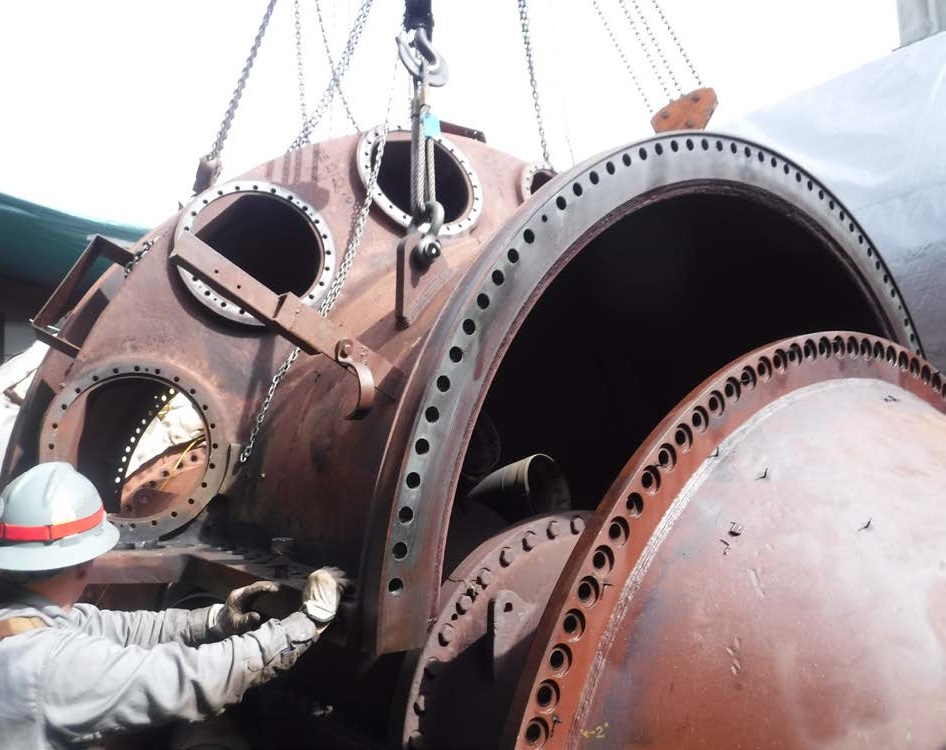

Almost finished with another Major Inspection.

Exciter has been reassembled, we’re getting closer…

Almost finished with another Major Inspection.

Exciter has been reassembled, we’re getting closer…

Turn-Key Inspections

Power Services Group (PSG) has the ability to provide full turnkey inspections on steam turbine generators for most OEM manufacturers. PSG provides total turnkey outage performance including technical direction, engineering, project management & coordination, supervision, labor, tooling, repairs, parts sourcing and/or manufacturing, and start-up support. We support fossil and nuclear steam turbines ranging from 1MW to 1,300MW for all major OEMs. We service all industry types including, but not limited to: industrial, paper/pulp, marine, steel/aluminum, chemical and petrochemical, utility, nuclear, and independent power producers.

Contact Us today to learn how we can help you with your next steam turbine project.

| Services Provided: | Common Repair Services: |

|

|

Power Services Group (PSG) executes combustion inspections, hot gas path inspections, and major inspections on combustion turbine generators all over the World. PSG provides total turnkey outage performance including technical direction, project management, coordination, supervision, labor, tooling, and start-up support. We provide combustion turbine services on the following unit types:

| OEM | Combustion Turbine Type |

| General Electric | Frame 3, 5, 6, 6B, 7, 7B, 7E, 7EA |

| Westinghouse | 251AA, 251B, 301G |

| Alstom | GT8, GT11 |

Contact Us today to learn how we can help you with your next combustion turbine inspection.

Turn-Key Inspections

Power Services Group (PSG) has the ability to provide full turnkey inspections on steam turbine generators for most OEM manufacturers. PSG provides total turnkey outage performance including technical direction, engineering, project management & coordination, supervision, labor, tooling, repairs, parts sourcing and/or manufacturing, and start-up support. We support fossil and nuclear steam turbines ranging from 1MW to 1,300MW for all major OEMs. We service all industry types including, but not limited to: industrial, paper/pulp, marine, steel/aluminum, chemical and petrochemical, utility, nuclear, and independent power producers.

Contact Us today to learn how we can help you with your next steam turbine project.

| Services Provided: | Common Repair Services: |

|

|

A Customized Plan

Most power producers are short-staffed and do not have the time and sometimes the expertise to prepare a comprehensive outage plan and workscope. That’s why we offer the option of providing our comprehensive Pre-Outage Planning Service independent of the award of the contract for inspection and repairs.

Our field project teams have the breadth of knowledge and experience to produce the highest quality planning product, with a workscope customized to your unit and its specific signature.

One of our qualified Technical Directors will visit your plant and prepare a customized report for your specific unit. The report will contain everything needed to plan your internal preparations for the outage and to prepare a comprehensive Request for Quote for the inspections and repairs.

A Basis For Your RFQ’s

Your customized Pre-Outage Plan will include everything you need to prepare a comprehensive Request for Quote for the necessary inspections and repairs. We will compile a summary of the findings from past inspections and develop a list of recommendations for potential repair work. We will prepare a comprehensive and detailed suggested Statement of Work for the outage, based on these findings and observations from a unit walk-down. Incorporating this information into your Request for Quote packages will yield “apples to apples” cost comparisons and few if any surprises on implementation.

A Task List For Your Facility

We will review your spare parts inventory and compile a list of recommended parts to have on hand prior to the outage. We will recommend disposal of any expired or unusable spare parts.

We will also prepare a Critical Path Method schedule based on the defined workscope. You can use this schedule to plan your expected outage duration and coordinate with any other activities to be conducted during this downtime.

What We Provide

The Pre-Outage Planning Package includes:

In summary, our Pre-Outage Planning deliverables to you will be:

Please CONTACT US today to learn more about how we can help you plan your next turbine outage.

Turn-Key Inspections

Power Services Group (PSG) has the ability to provide full turnkey inspections on steam turbine generators for most OEM manufacturers. PSG provides total turnkey outage performance including technical direction, engineering, project management & coordination, supervision, labor, tooling, repairs, parts sourcing and/or manufacturing, and start-up support. We support fossil and nuclear steam turbines ranging from 1MW to 1,300MW for all major OEMs. We service all industry types including, but not limited to: industrial, paper/pulp, marine, steel/aluminum, chemical and petrochemical, utility, nuclear, and independent power producers.

| Services Provided: | Common Repair Services: |

|

|

Power Services Group (PSG) has the ability to provide full turnkey inspections on steam turbine generators for most OEM manufacturers. PSG provides total turnkey outage performance including technical direction, engineering, project management & coordination, supervision, labor, tooling, repairs, parts sourcing and/or manufacturing, and start-up support. We support fossil and nuclear steam turbines ranging from 1MW to 1,300MW for all major OEMs. We service all industry types including, but not limited to: industrial, paper/pulp, marine, steel/aluminum, chemical and petrochemical, utility, nuclear, and independent power producers.

A Customized Plan

Most power producers are short-staffed and do not have the time and sometimes the expertise to prepare a comprehensive outage plan and workscope. That’s why we offers the option of providing our comprehensive Pre-Outage Planning Service independent of the award of the contract for inspection and repairs.

Our field project teams have the breadth of knowledge and experience to produce the highest quality planning product, with a workscope customized to your unit and its specific signature.

One of our qualified Technical Directors will visit your plant and prepare a customized report for your specific unit. The report will contain everything needed to plan your internal preparations for the outage and to prepare a comprehensive Request for Quote for the inspections and repairs.

A Basis For Your RFQ’s

Your customized Pre-Outage Plan will include everything you need to prepare a comprehensive Request for Quote for the necessary inspections and repairs. We will compile a summary of the findings from past inspections and develop a list of recommendations for potential repair work. We will prepare a comprehensive and detailed suggested Statement of Work for the outage, based on these findings and observations from a unit walk-down. Incorporating this information into your Request for Quote packages will yield “apples to apples” cost comparisons and few if any surprises on implementation.

A Task List For Your Facility

We will review your spare parts inventory and compile a list of recommended parts to have on hand prior to the outage. We will recommend disposal of any expired or unusable spare parts.

We will also prepare a Critical Path Method schedule based on the defined workscope. You can use this schedule to plan your expected outage duration and coordinate with any other activities to be conducted during this downtime.

What We Provide

The Pre-Outage Planning Package includes:

In summary, our Pre-Outage Planning deliverables to you will be:

Please CONTACT US today to learn more about how we can help you plan your next turbine outage.

With over 34 years of experience performing turbine generator maintenance and repair services, PSG knows what customers expect when it comes to managing an outage.

A PSG inspection is more than open, clean and close. Our quote includes all of the work implicit to your Statement of Work to achieve a comprehensive inspection – minimizing Change Order surprises. We examine every relevant aspect of the power train. We perform meaningful measurements of components and clearances and record multiple measurements at each location. Recording this extra data allows us to better identify potential problems and enables us to establish trends across successive inspections.

We have the right resources and the right people to provide professional and total turnkey outage service. That is, PSG will procure and manage all resources needed to complete your outage, and you can rest assured that our outage scope will be taken care of professionally and efficiently.

When you choose PSG for your turbine generator services, we immediately begin strategizing for your outage with our experienced project teams, our project-specific planning, our learned and tested processes, our customized tooling, and our attitude of safety and customer service.

If we find damage or deviation to specification, we perform a full assessment to diagnose the root causes behind the symptom and recommend actions to prevent its return. These recommendations may include operational or maintenance changes. The goal of our comprehensive measurements and proactive approach to repairs is the elimination of future forced outages.

Power Services Group brings you a wide range of services specific to industries like yours, offering exceptional value and responsiveness. We can hit the ground running and deliver results so you can have peace of mind and your equipment is always available.

125 SW 3rd Place, Suite 300

Cape Coral, FL 33991

Phone: (800) 226-7557