Compressor Failures – Stator Vane Lock-up

Some compressor failures have been attributed to “lock-up” of the stator vanes. The vane roots are designed to rock slightly at their roots when moved with your hand. Rust and debris can inhibit this movement. An immobile vane changes the stress profile on the vane which can cause cracking and potential failure. Mechanics should check for proper movement at each inspection.

Removing locked-up stator vanes has been a challenge for service providers. The OEM has come up with material upgrades to address the corrosion problems in these areas. The compressor upgrades are designed to reduce the potential for compressor failures and lock-up of the stator vanes. Some providers use destructive methods to cut out the vanes, potentially damaging the compressor casing. The OEM recommends the use of their (expensive) special tooling to reduce and hopefully prevent casing damage. An alternate method that TGM®has used very successfully is a process of heating and quenching. Heating the locked-up stator vane segments with a torch and quickly quenching the vane with cold water will typically free the vane segment for removal without damaging the casing. The process of heating and quenching (applied by an experienced team) can save time and money while reducing and hopefully eliminating damage to the compressor casing. TGM® can provide its expertise in removing stubborn stator vane segments and, if needed, quickly replace damaged stator vanes to get the customer back on line as soon as possible.

TGM®‘s experienced combustion turbine Technical Directors and crews often delight customers by providing innovative methods that can efficiently and permanently solve issues and get the customer back on line to make power. Early detection of shim migration and stator vane problems can be performed by TGM®through borescope inspections and eddy current NDE.

TGM®‘s comprehensive borescope diagnostics can provide recommendations and solutions to address many other compressor issues. Contact Us to find out how we can help.

Ever heard the adage “Close is only good in horseshoes and hand grenades”? We think that close calls are also important to maintaining a safe work environment. Exposing, analyzing, communicating and learning from these events is an important part of TGM®‘s safety program. We call these experiences “Near Miss” events. The resolution of one of our recent “Near Miss” events may benefit your operation.

Ever heard the adage “Close is only good in horseshoes and hand grenades”? We think that close calls are also important to maintaining a safe work environment. Exposing, analyzing, communicating and learning from these events is an important part of TGM®‘s safety program. We call these experiences “Near Miss” events. The resolution of one of our recent “Near Miss” events may benefit your operation. TGM® takes these near misses very seriously. An immediate stand-down is ordered for that phase of the work and the circumstances are documented in both words and pictures. The corporate Safety Director is alerted and a discussion begins on how best to remedy the current situation in order to safely resume the task. The incident and its immediate resolution is communicated to all Technical Directors so they can beware of the hazard. This particular incident was judged a systemic hazard, so we began looking for a systemic solution. A reminder of the incident was also recorded in our latest Safety Slogan: “I NEVER miss” is NEVER an acceptable answer! (See other slogan winners

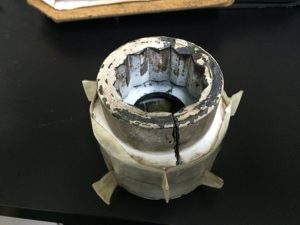

TGM® takes these near misses very seriously. An immediate stand-down is ordered for that phase of the work and the circumstances are documented in both words and pictures. The corporate Safety Director is alerted and a discussion begins on how best to remedy the current situation in order to safely resume the task. The incident and its immediate resolution is communicated to all Technical Directors so they can beware of the hazard. This particular incident was judged a systemic hazard, so we began looking for a systemic solution. A reminder of the incident was also recorded in our latest Safety Slogan: “I NEVER miss” is NEVER an acceptable answer! (See other slogan winners  One recent hydraulic socket failure demonstrated the importance of our current practices. We have a set of specialized sockets in each tool set which are dedicated for hydraulic use only and painted white to distinguish them from other sockets. The sockets and the wrenches are regularly inspected for damage when the tool set is returned to the warehouse after a job. An outage team can also get a replacement socket if they feel one is damaged or otherwise subject to failure. Before use, a socket is wrapped in a specialized tape which will contain the shattered pieces if it fails. The picture below demonstrates the effectiveness of these practices. Without the tape, the socket could have flown across the turbine deck.

One recent hydraulic socket failure demonstrated the importance of our current practices. We have a set of specialized sockets in each tool set which are dedicated for hydraulic use only and painted white to distinguish them from other sockets. The sockets and the wrenches are regularly inspected for damage when the tool set is returned to the warehouse after a job. An outage team can also get a replacement socket if they feel one is damaged or otherwise subject to failure. Before use, a socket is wrapped in a specialized tape which will contain the shattered pieces if it fails. The picture below demonstrates the effectiveness of these practices. Without the tape, the socket could have flown across the turbine deck.