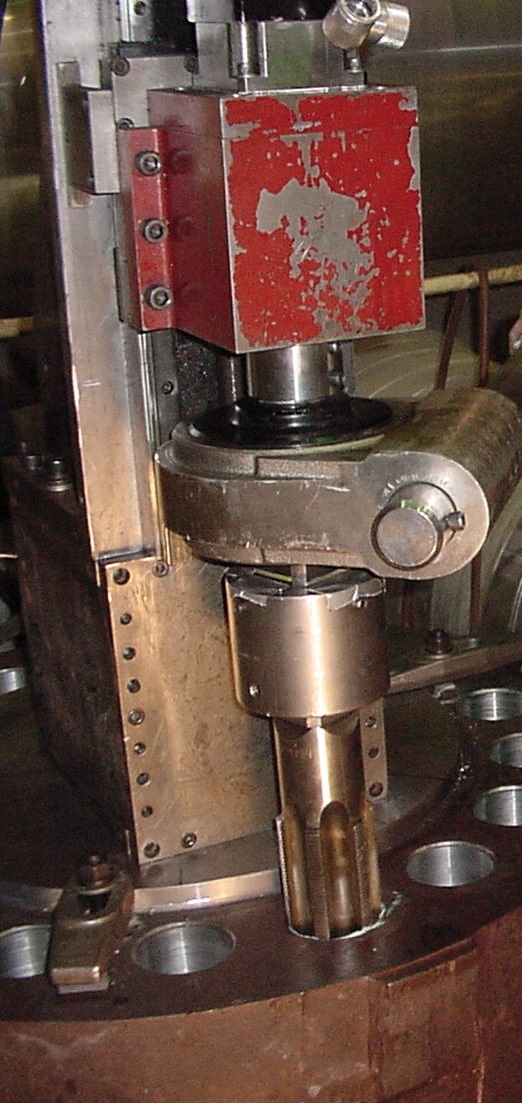

Steam Path Repairs

PSG subsidiary company, Orbital Energy Services, provides steam path repair services for your steam turbine rotating and stationary components. Our company maintains an extensive inventory of steam path repair equipment and employs some of the most highly skilled and experienced personnel in the industry. Visit our website to learn more!