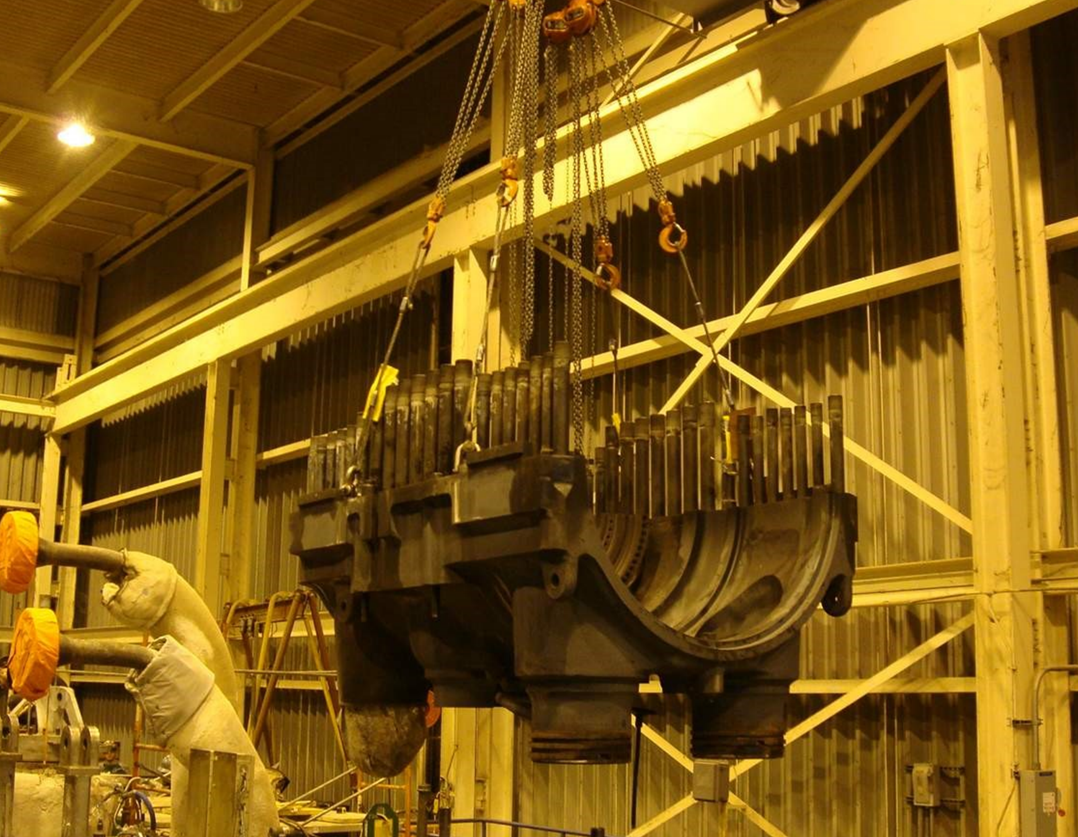

Turn-Key Inspections

Power Services Group (PSG) has the ability to provide full turnkey inspections on steam turbine generators for most OEM manufacturers. PSG provides total turnkey outage performance including technical direction, engineering, project management & coordination, supervision, labor, tooling, repairs, parts sourcing and/or manufacturing, and start-up support. We support fossil and nuclear steam turbines ranging from 1MW to 1,300MW for all major OEMs. We service all industry types including, but not limited to: industrial, paper/pulp, marine, steel/aluminum, chemical and petrochemical, utility, nuclear, and independent power producers.

Contact Us today to learn how we can help you with your next steam turbine project.

| Services Provided: |

Common Repair Services: |

- Open, Clean, Inspect, Close (Outage Services)

- Valve & Bearing Inspection and Repairs

- Steam Path Component Inspection and Repairs

- Major Overhaul Planning and Execution

- Shop Repair Services

- Field Repair Services

- Forced Outage Responsiveness

- Multi-Year Service Agreements

- Engineering/Consulting

- Reverse Engineering

- Parts Manufacturing

- Generator Inspection, Testing, and Repair

- Running Condition Assessments

- Unit Installation/Relocation

|

- Nozzle and Diaphragm Refurbishment

- Blade Ring Refurbishment

- Seal and Packing Machining and Replacement

- NDE Services

- Dish Removal and Re-rounding Services

- Blade/Bucket Replacement

- Erosion Shield Replacement

- Lashing Lug Weld Repair

- Tennon Welding and Refurbishment

- Cover Replacement

- Bore Plug Removal and Installation

- Balancing Services

- Valve Reconditioning

- In-House Nitriding Services

- Stellite Application Services

|