Where is Mr. Turbine Today?

Mr. Turbine recently went on a canoe trip and lost his paddle over the side. Getting it back was an oar-deal!

Mr. Turbine recently went on a canoe trip and lost his paddle over the side. Getting it back was an oar-deal!

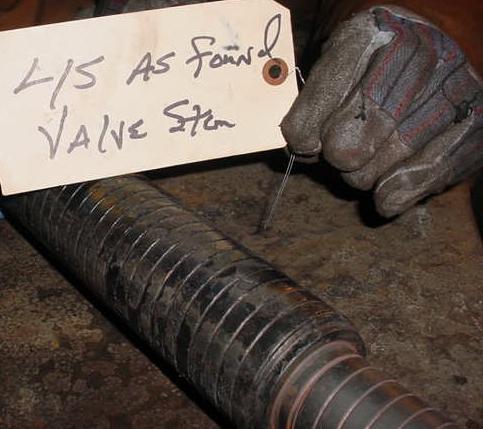

Power Services Group has developed and proven advanced valve component repair methods. The material enhancements we offer can translate into increased durability and service life, and ultimately, reduced maintenance costs. All parts supplied by Power Services Group meet or exceed the OEM original quality specs, with a full warranty against defects from time of purchase. Visit our website to learn more!

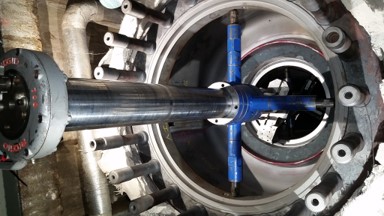

Non-Return Valves (NRV) need to be exercised on a regular basis to prevent water induction. This occurs when cooler steam condenses in the pipes and feeds back into the turbine. Water induction can cause serious damage, often referred to as a turbine rotor short condition. Visit our website to learn more!

This boat tells good stories. They always have a ferry-tail ending!

Flange facing is a on-site machining service conducted on a flange to avoid leakages and corrosion. This service helps maintain the joint integrity required between two flange surfaces. Flanges constantly experience damage from corrosion or erosion due to turbulent flow, impacts with other components during construction or installation or cuts from gasket leaks.

Visit PSG To learn more about this service.

What do you call a factory that makes okay products? Satisfactory. Mr. Turbine says call the turbine experts for service that’s well above satisfactory!

Power Services Group has developed and proven advanced processes to increase durability and prolong the life of steam turbine components. We provide 100% quality guaranteed aftermarket parts, manufactured at our ISO 9001:2015 certified facility. Contact us today to learn how we can provide you with affordable quality steam turbine components.

Visit our website to learn more about how we can help you with all of your steam turbine needs.

A thrust bearing is a type of bearing that helps rotation and resists thrust at the same time. The main function of a thrust bearing is to resist any axial force applied to the rotor and maintain its position. At PSG we have trained & experienced employees for extensive any turbine. To learn more please visit our website for more information.

Mr. Turbine says the street art in London is very ad-mural-able.

Visit our website to see where Mr. Turbine goes next!

We provide reverse engineering and precision replacement part manufacturing of valve components for virtually all types of turbine valves. Our company maintains one of the industry’s most advanced valve repair equipment inventories.

Please visit our website or call us to learn more.

Power Services Group brings you a wide range of services specific to industries like yours, offering exceptional value and responsiveness. We can hit the ground running and deliver results so you can have peace of mind and your equipment is always available.

125 SW 3rd Place, Suite 300

Cape Coral, FL 33991

Phone: (800) 226-7557