Safety and Hand Grenades

Ever heard the adage “Close is only good in horseshoes and hand grenades”? We think that close calls are also important to maintaining a safe work environment. Exposing, analyzing, communicating and learning from these events is an important part of TGM®‘s safety program. We call these experiences “Near Miss” events. The resolution of one of our recent “Near Miss” events may benefit your operation.

Ever heard the adage “Close is only good in horseshoes and hand grenades”? We think that close calls are also important to maintaining a safe work environment. Exposing, analyzing, communicating and learning from these events is an important part of TGM®‘s safety program. We call these experiences “Near Miss” events. The resolution of one of our recent “Near Miss” events may benefit your operation.

Our mechanics were using a striking wrench to loosen bolts on a turbine. One mechanic held a rope attached to the end of the wrench in order to apply a slight torque to keep the wrench seated on the nut. Another mechanic struck the wrench with an 8 pound hammer. Naturally, the holder of the rope is standing along the path of the hammer swing. The rope is normally long enough to position the mechanic well outside the hammer’s path. In this recent case, space was tight and the rope was too short. No problem if every hammer blow strikes the wrench. The mechanic was confident, declaring “I never miss!”. Except he did, and struck his partner in his safety glasses. His partner suffered a slight cut from the glasses but was

otherwise OK. (See adjacent picture.)

TGM® takes these near misses very seriously. An immediate stand-down is ordered for that phase of the work and the circumstances are documented in both words and pictures. The corporate Safety Director is alerted and a discussion begins on how best to remedy the current situation in order to safely resume the task. The incident and its immediate resolution is communicated to all Technical Directors so they can beware of the hazard. This particular incident was judged a systemic hazard, so we began looking for a systemic solution. A reminder of the incident was also recorded in our latest Safety Slogan: “I NEVER miss” is NEVER an acceptable answer! (See other slogan winners HERE.)

TGM® takes these near misses very seriously. An immediate stand-down is ordered for that phase of the work and the circumstances are documented in both words and pictures. The corporate Safety Director is alerted and a discussion begins on how best to remedy the current situation in order to safely resume the task. The incident and its immediate resolution is communicated to all Technical Directors so they can beware of the hazard. This particular incident was judged a systemic hazard, so we began looking for a systemic solution. A reminder of the incident was also recorded in our latest Safety Slogan: “I NEVER miss” is NEVER an acceptable answer! (See other slogan winners HERE.)

Our solution is a specialized tool which allows a mechanic to stand perpendicular to the path of the hammer blow while holding the striking wrench. The picture at the top of the article shows a mechanic setting the wrench on a nut. He will get out of the way after another mechanic grabs the end of the tool. A second mechanic will strike the wrench. An added benefit is that the wrench will not go flying if it is dislodged from the nut.

Hydraulic wrenches are also used to remove nuts in close quarters. TGM® uses this tool where warranted. Hydraulic wrench manufacturers maintain explicit warnings regarding their use and require operators to have specialized training. The hydraulic sockets can shatter even when used properly. We have experienced several Near Miss incidents in their use, and have discussed the dangers in several other Turbine Tips. (See below).

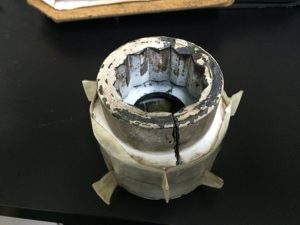

One recent hydraulic socket failure demonstrated the importance of our current practices. We have a set of specialized sockets in each tool set which are dedicated for hydraulic use only and painted white to distinguish them from other sockets. The sockets and the wrenches are regularly inspected for damage when the tool set is returned to the warehouse after a job. An outage team can also get a replacement socket if they feel one is damaged or otherwise subject to failure. Before use, a socket is wrapped in a specialized tape which will contain the shattered pieces if it fails. The picture below demonstrates the effectiveness of these practices. Without the tape, the socket could have flown across the turbine deck.

One recent hydraulic socket failure demonstrated the importance of our current practices. We have a set of specialized sockets in each tool set which are dedicated for hydraulic use only and painted white to distinguish them from other sockets. The sockets and the wrenches are regularly inspected for damage when the tool set is returned to the warehouse after a job. An outage team can also get a replacement socket if they feel one is damaged or otherwise subject to failure. Before use, a socket is wrapped in a specialized tape which will contain the shattered pieces if it fails. The picture below demonstrates the effectiveness of these practices. Without the tape, the socket could have flown across the turbine deck.

Please Contact Us if you would like more information on procuring or using any of these tools.

We emphasize a lot of “on the job” safety, but what about “off the job” safety? We have a responsibility to use what we learned in all of our safety training and apply it to everyday safety. A large part of safety training is to help you form a safe attitude – to encourage you to want to be safe and to think safety at all times. It is important not just to your employer, but to you and your family as well. What you do on your own time is your own business, but it is only natural that we are concerned about each other’s welfare, both on and off the job. Only an immature person would deliberately leave safety at work. However, there are times when we all get a little careless.

We emphasize a lot of “on the job” safety, but what about “off the job” safety? We have a responsibility to use what we learned in all of our safety training and apply it to everyday safety. A large part of safety training is to help you form a safe attitude – to encourage you to want to be safe and to think safety at all times. It is important not just to your employer, but to you and your family as well. What you do on your own time is your own business, but it is only natural that we are concerned about each other’s welfare, both on and off the job. Only an immature person would deliberately leave safety at work. However, there are times when we all get a little careless. A young construction worker was killed the same day his wife was coming home from the hospital with their first child. How did this occur? A crane was transporting a heavy, bulky section six or seven feet in the air to clear other objects. The load was guided by tag lines which were used by all of the workers except this young man. Although warned by his foreman to use the line, he didn’t. A lifting pad gave way and he was killed instantly.

A young construction worker was killed the same day his wife was coming home from the hospital with their first child. How did this occur? A crane was transporting a heavy, bulky section six or seven feet in the air to clear other objects. The load was guided by tag lines which were used by all of the workers except this young man. Although warned by his foreman to use the line, he didn’t. A lifting pad gave way and he was killed instantly. It’s that time of year again – summertime – hot and unbearable weather. This year is starting off in pretty much the same pattern as years gone by. All over the U.S we are seeing extremely high heat temperatures, especially in the western portion where temperatures are reaching an average of 112° to 128° degrees. Many people are exposed to heat on some jobs, outdoors, or in hot indoor environments. Operations involving high air temperatures, radiant heat sources, high humidity, direct physical contact with hot objects, or strenuous physical activities have a high potential for causing heat-related illness.

It’s that time of year again – summertime – hot and unbearable weather. This year is starting off in pretty much the same pattern as years gone by. All over the U.S we are seeing extremely high heat temperatures, especially in the western portion where temperatures are reaching an average of 112° to 128° degrees. Many people are exposed to heat on some jobs, outdoors, or in hot indoor environments. Operations involving high air temperatures, radiant heat sources, high humidity, direct physical contact with hot objects, or strenuous physical activities have a high potential for causing heat-related illness. Contrary to popular opinion, all workers can prevent themselves from getting hurt. The easy way to avoid pain is to observe how others have taken risks and been injured, rather than learning the hard way–from your own injury. That’s common sense! By avoiding unsafe acts and practicing common sense, your work will go smoother, with less chance for accidents.

Contrary to popular opinion, all workers can prevent themselves from getting hurt. The easy way to avoid pain is to observe how others have taken risks and been injured, rather than learning the hard way–from your own injury. That’s common sense! By avoiding unsafe acts and practicing common sense, your work will go smoother, with less chance for accidents. Falls are one of the leading causes of unintentional injuries in the United States, accounting for nearly 8.6 million visits to the emergency room. Adults 55 and older are more prone to being victims of falls, and the resulting injuries can diminish the ability to lead active, independent lives. The number of fall deaths among adults 65 or older is four times the number of fall deaths among all other age groups.

Falls are one of the leading causes of unintentional injuries in the United States, accounting for nearly 8.6 million visits to the emergency room. Adults 55 and older are more prone to being victims of falls, and the resulting injuries can diminish the ability to lead active, independent lives. The number of fall deaths among adults 65 or older is four times the number of fall deaths among all other age groups. Statistics indicate that knives cause more disabling injuries than any other hand tool. People in all occupations are injured by knives – a stock boy in a supermarket produce department or a mechanic opening a box or cutting rubber. We are all exposed to knife injuries only because a knife is a very handy and commonly used tool.

Statistics indicate that knives cause more disabling injuries than any other hand tool. People in all occupations are injured by knives – a stock boy in a supermarket produce department or a mechanic opening a box or cutting rubber. We are all exposed to knife injuries only because a knife is a very handy and commonly used tool.