Inadequate Oil Supply: When a Backup isn’t a Backup

This is Part One of a three part series on steam turbine tips, discussing the challenge of inadequate oil supply.

The International Association of Engineering Insurers has found that the loss of oil pressure causes the highest frequency of failure in steam turbines worldwide.

Most of these steam turbine failures are caused by an unreliable backup system to maintain oil pressure to the bearings should the primary AC-driven lube oil pumps fail. These AC motors are powered by either the turbine’s output or the grid—causing a failure if the turbine or generator trips—or if there is an external outage.

Most of these steam turbine failures are caused by an unreliable backup system to maintain oil pressure to the bearings should the primary AC-driven lube oil pumps fail. These AC motors are powered by either the turbine’s output or the grid—causing a failure if the turbine or generator trips—or if there is an external outage.

Modern turbines have backup powered DC oil pumps mounted on the oil tank, which are triggered by a pressure switch in the event of a loss in oil pressure. With this in mind, it is very important to conduct tests with the AC and DC oil pumps during scheduled maintenance inspections to ensure that the DC pump engages as required.

Such tests can be referred to as cascade pump pressure inspections. In addition, the tests will confirm the pressures when the DC oil pump will engage after the AC oil pump is actually turned off.

Another best practice is to verify backup batteries on a regular basis, when the unit is down, and mandatory tests should be performed before the unit is placed in operation after an overhaul.

Older turbines can use steam-driven pumps as backup. On these designs, a pressure regulator will sense the drop-in bearing oil pressure and turn on the steam supply to the blade wheel of the pump. But while these pumps are usually very reliable, they still must be manually tested on a regular basis and after an overhaul.

Care must also be taken to not overspeed the pump or it will potentially cause internal component damage and may even completely destroy the pump.

Some older turbines use gravity lube oil tanks. These tanks are mounted above the unit on stands and are controlled by a check valve type of arrangement. In such cases, there are no pumps involved—gravity provides the bearings with sufficient lubrication in an emergency situation. While less complicated than DC or steam powered backups, their operation must still be routinely checked.

The bottom line is, that a backup is not a backup unless it is reliable. And it can only be reliable if it is tested.

Do you have questions about your steam turbine backup system? Contact PSG today to explore how we can provide support and maintenance options to help you avoid backup system problems.

The Power Services Group, Inc. field service team recently completed a turnkey B-inspection on an Alstom STF steam turbine rated at 190 megawatts output. The work scope included disassembly, inspection and reassembly of the HP stop valve, HP control valve, IP stop valves, IP control valves, bearings #1 through 5, and the thrust bearing. PSG’s turnkey solution supplied outage management, technical direction, supervision, craft labor, outage tooling, consumables, non-destructive testing, and commissioning and start-up services. The project was aggressively scheduled for 10 days mechanical duration, with a two shift around the clock coverage. Completed safely and without rework, the project was one day ahead of schedule. Another great example of PSG’s expertise with Alstom steam turbines, we provide our clients with a proven and trusted alternative to the OEM.

The Power Services Group, Inc. field service team recently completed a turnkey B-inspection on an Alstom STF steam turbine rated at 190 megawatts output. The work scope included disassembly, inspection and reassembly of the HP stop valve, HP control valve, IP stop valves, IP control valves, bearings #1 through 5, and the thrust bearing. PSG’s turnkey solution supplied outage management, technical direction, supervision, craft labor, outage tooling, consumables, non-destructive testing, and commissioning and start-up services. The project was aggressively scheduled for 10 days mechanical duration, with a two shift around the clock coverage. Completed safely and without rework, the project was one day ahead of schedule. Another great example of PSG’s expertise with Alstom steam turbines, we provide our clients with a proven and trusted alternative to the OEM. At STUG 2015, 50% of users of the GE D11 Steam Turbine reported cracking issues in the HP/IP shell, especially the N2 packing gland and shell fit. These cracks create the potential for forced shutdowns and relatively long outage cycle times.

At STUG 2015, 50% of users of the GE D11 Steam Turbine reported cracking issues in the HP/IP shell, especially the N2 packing gland and shell fit. These cracks create the potential for forced shutdowns and relatively long outage cycle times. At STUG 2015, a survey revealed that 43% of D11 combined cycle users perform valve freedom testing on a daily basis, while 38% perform it on a weekly basis. The potential accumulation of deposits is a little more critical in these high temperature units, but exercising valves is important on any unit. For instance, on a recent 40MW forced outage, TGM® serviced a stuck Emergency Stop Valve that was exercised every week. How does one determine the “safe” frequency?

At STUG 2015, a survey revealed that 43% of D11 combined cycle users perform valve freedom testing on a daily basis, while 38% perform it on a weekly basis. The potential accumulation of deposits is a little more critical in these high temperature units, but exercising valves is important on any unit. For instance, on a recent 40MW forced outage, TGM® serviced a stuck Emergency Stop Valve that was exercised every week. How does one determine the “safe” frequency? Another result of exfoliation (or any other hard particle steam contamination) is erosion

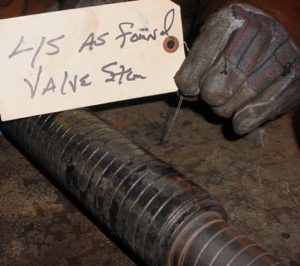

Another result of exfoliation (or any other hard particle steam contamination) is erosion To reduce the chance of binding, OEM’s have increased the operational clearances for these high temperature machines over the design’s original upper limit. These clearances can be achieved during major inspections. Any blue blush (exfoliation) will be removed by sandblasting or by hand with emery strips (fine sandpaper grit). Stems (shafts) can be used over again and this blue blush build-up once cleaned can also be helpful in maintaining the desired clearance between shaft and bushing components.

To reduce the chance of binding, OEM’s have increased the operational clearances for these high temperature machines over the design’s original upper limit. These clearances can be achieved during major inspections. Any blue blush (exfoliation) will be removed by sandblasting or by hand with emery strips (fine sandpaper grit). Stems (shafts) can be used over again and this blue blush build-up once cleaned can also be helpful in maintaining the desired clearance between shaft and bushing components. Steam turbines can reliably run for 30, 40 years or more. However everything wears and eventually fits, finishes and tolerances become unacceptable. For instance, the rabbet fit on the coupling faces of a three bearing machine will eventually become loose and in need of repair. This defect can cause misalignment, abnormal vibration levels and undue stresses on the rotors.

Steam turbines can reliably run for 30, 40 years or more. However everything wears and eventually fits, finishes and tolerances become unacceptable. For instance, the rabbet fit on the coupling faces of a three bearing machine will eventually become loose and in need of repair. This defect can cause misalignment, abnormal vibration levels and undue stresses on the rotors. The steam turbine gland steam seal system is designed to keep steam from leaking out of the turbine and to prevent air from leaking into the turbine. A gland seal system can be as simple as a spray chamber, loop seal and a steam ejector or as complex as surface condensers, air blowers or vacuum pumps. Simple or complex, the system requires timely care and maintenance. An improperly balanced gland system can lead to water in the lubricating oil, loss of vacuum or accelerated wear on the packing gland components.

The steam turbine gland steam seal system is designed to keep steam from leaking out of the turbine and to prevent air from leaking into the turbine. A gland seal system can be as simple as a spray chamber, loop seal and a steam ejector or as complex as surface condensers, air blowers or vacuum pumps. Simple or complex, the system requires timely care and maintenance. An improperly balanced gland system can lead to water in the lubricating oil, loss of vacuum or accelerated wear on the packing gland components. Contaminated steam can seriously impair the performance and reliability of the turbine. Dissolved minerals can cause an accumulation of deposits on surfaces, impeding fluid flow. A deposit thickness of only 3 mils on the convex surface of buckets can cause an increase of 1 to 2 % in the fuel bill and a 1% reduction in peaking capacity. (See the companion article

Contaminated steam can seriously impair the performance and reliability of the turbine. Dissolved minerals can cause an accumulation of deposits on surfaces, impeding fluid flow. A deposit thickness of only 3 mils on the convex surface of buckets can cause an increase of 1 to 2 % in the fuel bill and a 1% reduction in peaking capacity. (See the companion article  The final Turbine Generator Tip in this series discusses two common steam turbine casing problems – Distortion and Erosion. The repair methods employed – grinding, mechanical repair, welding and stress relief – have their own set of considerations which were covered in previous portions of the series.

The final Turbine Generator Tip in this series discusses two common steam turbine casing problems – Distortion and Erosion. The repair methods employed – grinding, mechanical repair, welding and stress relief – have their own set of considerations which were covered in previous portions of the series. Welding is a common method to repair turbine casing cracks, but it must be applied with consideration. Most turbine casing alloys can be welded using either of two distinct procedures: stress relieved and non-stress relieved. The procedure selected is often dictated by time and cost restraints.

Welding is a common method to repair turbine casing cracks, but it must be applied with consideration. Most turbine casing alloys can be welded using either of two distinct procedures: stress relieved and non-stress relieved. The procedure selected is often dictated by time and cost restraints. This three part Turbine Generator Tip discusses the most common steam turbine casing problems: cracking, distortion and erosion. Most units can be repaired by grinding, welding or by pre-stressed mechanical methods. Finite element calculations show that in many cases, repairs can overcome some of the original design weaknesses and extend useful life by up to 20 years. But before proceeding with a repair, understand the mechanisms of both the casing damage and the proposed repair. Improper repair can be useless or worse.

This three part Turbine Generator Tip discusses the most common steam turbine casing problems: cracking, distortion and erosion. Most units can be repaired by grinding, welding or by pre-stressed mechanical methods. Finite element calculations show that in many cases, repairs can overcome some of the original design weaknesses and extend useful life by up to 20 years. But before proceeding with a repair, understand the mechanisms of both the casing damage and the proposed repair. Improper repair can be useless or worse.