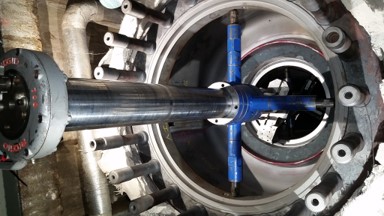

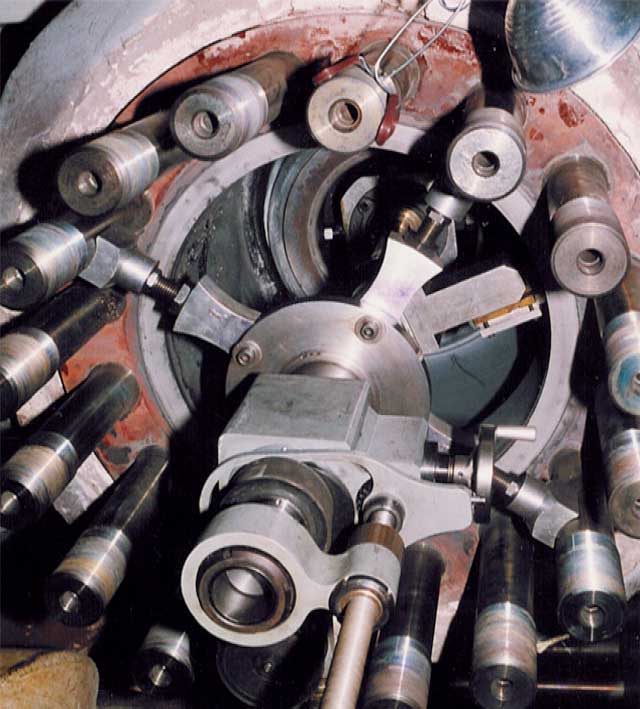

Valve Repairs

Material cracking and delamination has been observed on steam turbine valve seats on certain types of steam turbines. Delamination of the weld hard facing from the valve body can result in collateral damage to components in the turbine or valve failure. We offer a variety of solutions for this issue and can discuss your specific circumstance to choose which solution may be best for you. Visit our website to learn more about our steam turbine valve repair services.