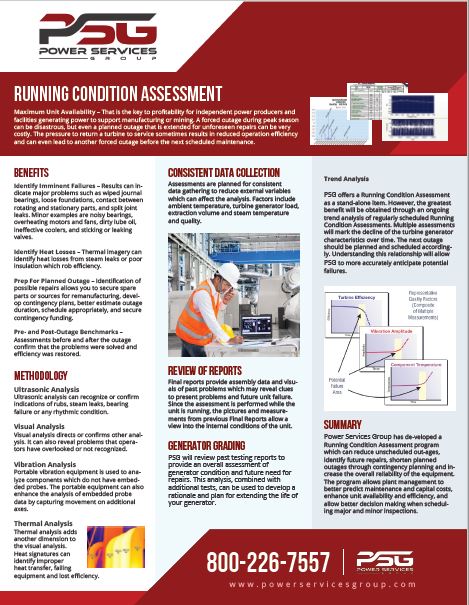

Want to learn more about Power Services Group? Schedule a Virtual Meeting today!

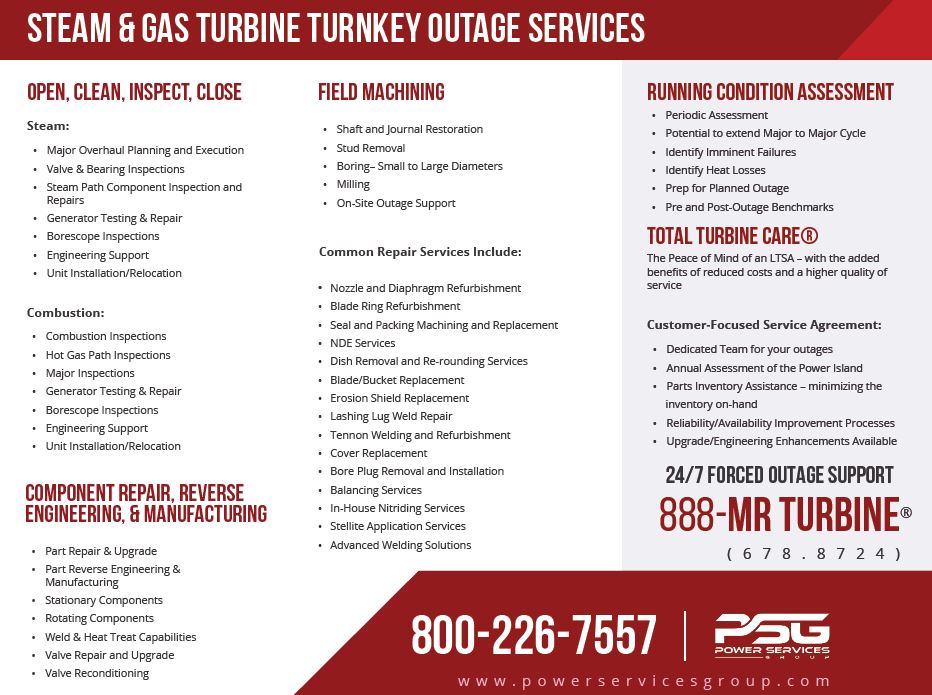

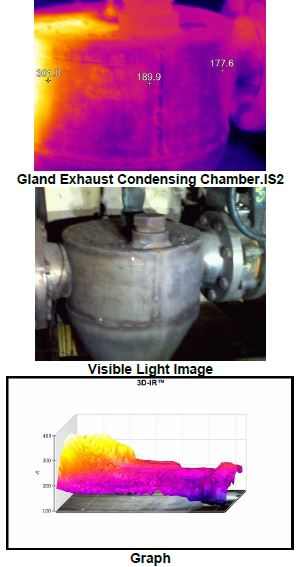

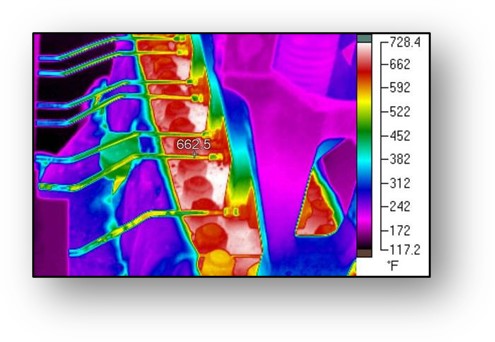

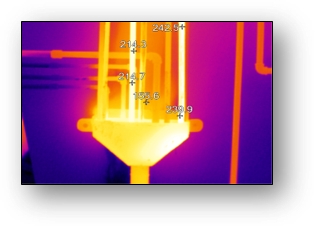

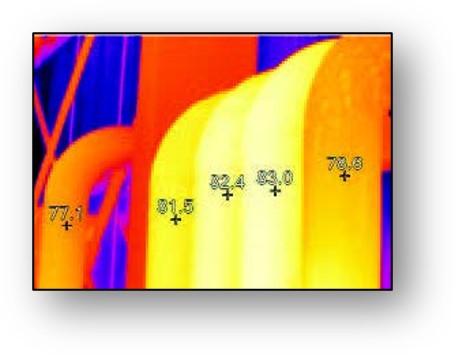

If you’ve ever wanted to learn more about the capabilities Power Services Group can provide your facility we can conduct a Virtual Meeting at a time of your choosing, on the platform of your choosing (Zoom, GoToMeeting, Webex, Skype, etc.). Whether it be our Steam Turbine Valve Repair Facility and capabilities, or our Running Condition Assessment program for extending your major to major cycle, we can tailor a virtual meeting to suit your needs and provide you with alternatives to servicing your turbine. If there are any turbine maintenance topics that you would like to learn more about please contact us by clicking the link HERE to send an email to us, or call us at 800-226-7557. If you prefer to simply have our brochures emailed or sent in a hard copy folder we can do that as well. Simply add “Email Brochures” or “Mail Brochures” in the body of the message. We look forward to providing you with turbine maintenance alternatives for your facility.