Contact us today to learn how we can provide you with high quality/low cost valve components for your Steam Turbine. We manufacture a variety of valve components for various Steam Turbine OEM types for the fossil and nuclear industries.

Whether it be to replenish your stock or for an upcoming turbine outage need, we have a solution for you.

We can also reverse engineer and manufacture components through the simple process outlined below.

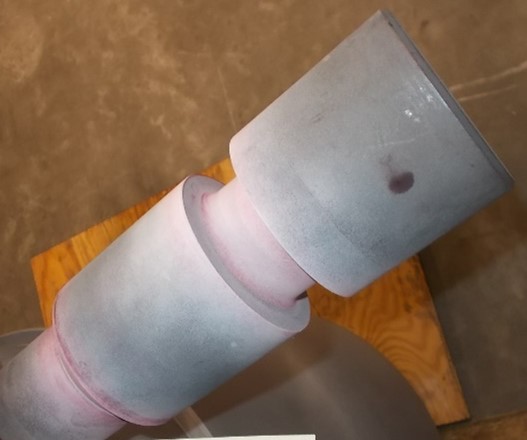

- Sample Received– Whether it’s a stock item or an item made to order for a special application, the process begins with a new or used sample.

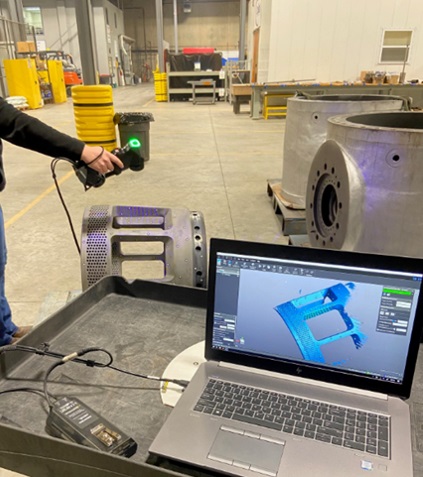

- Reverse Engineering – After receiving your sample, we confirm all required properties (dimensions, hardness, material composition) using our state of the art equipment.

- Design – From the reverse engineering data, a detailed CAD manufacturing drawing is created in accordance with international design standards.

- Price Estimate – A price estimate is provided for the finished part. Typically, savings are in the range of 15-30% under standard retail pricing. More savings can be realized as production quantities increase.

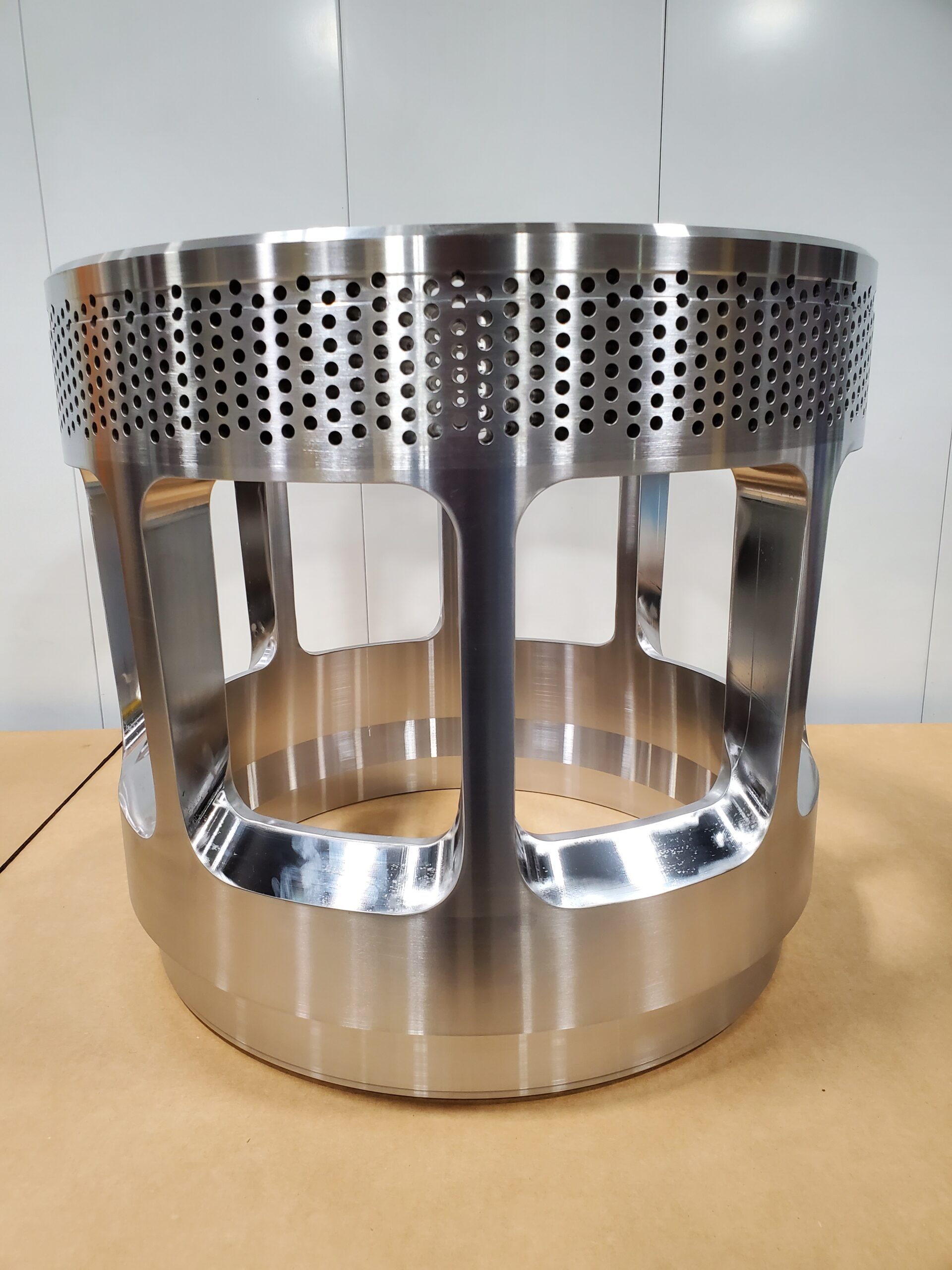

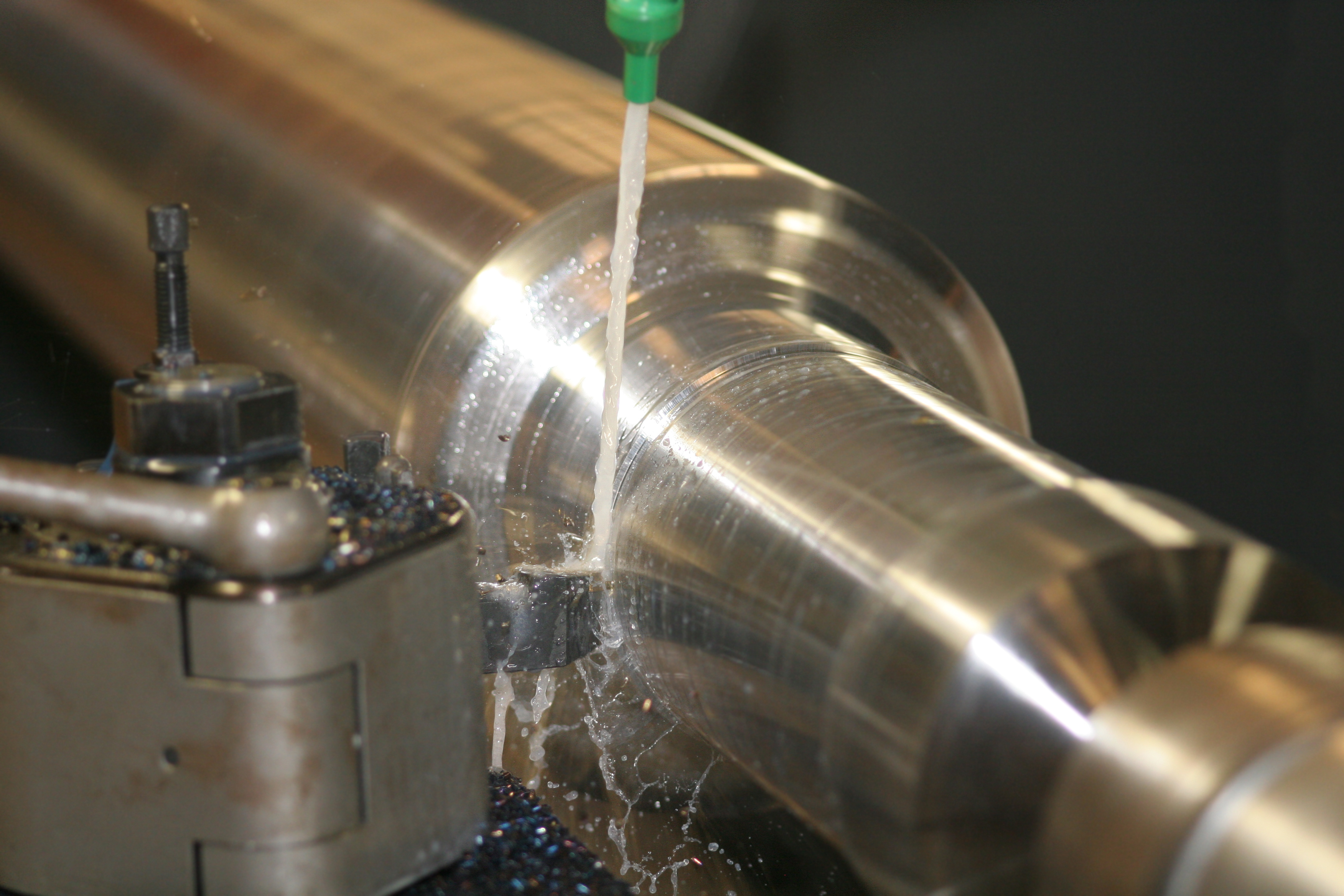

- Manufacture – Upon agreement on the design and price, we manufacture the part, updating you on the production status along the way. After passing a stringent quality inspection, parts will ship immediately.

We look forward to developing a custom plan to help you improve quality and reduce the cost of your critical steam turbine valve components.