Valve Repairs

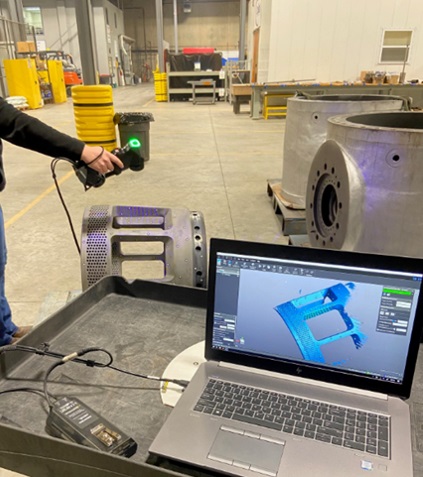

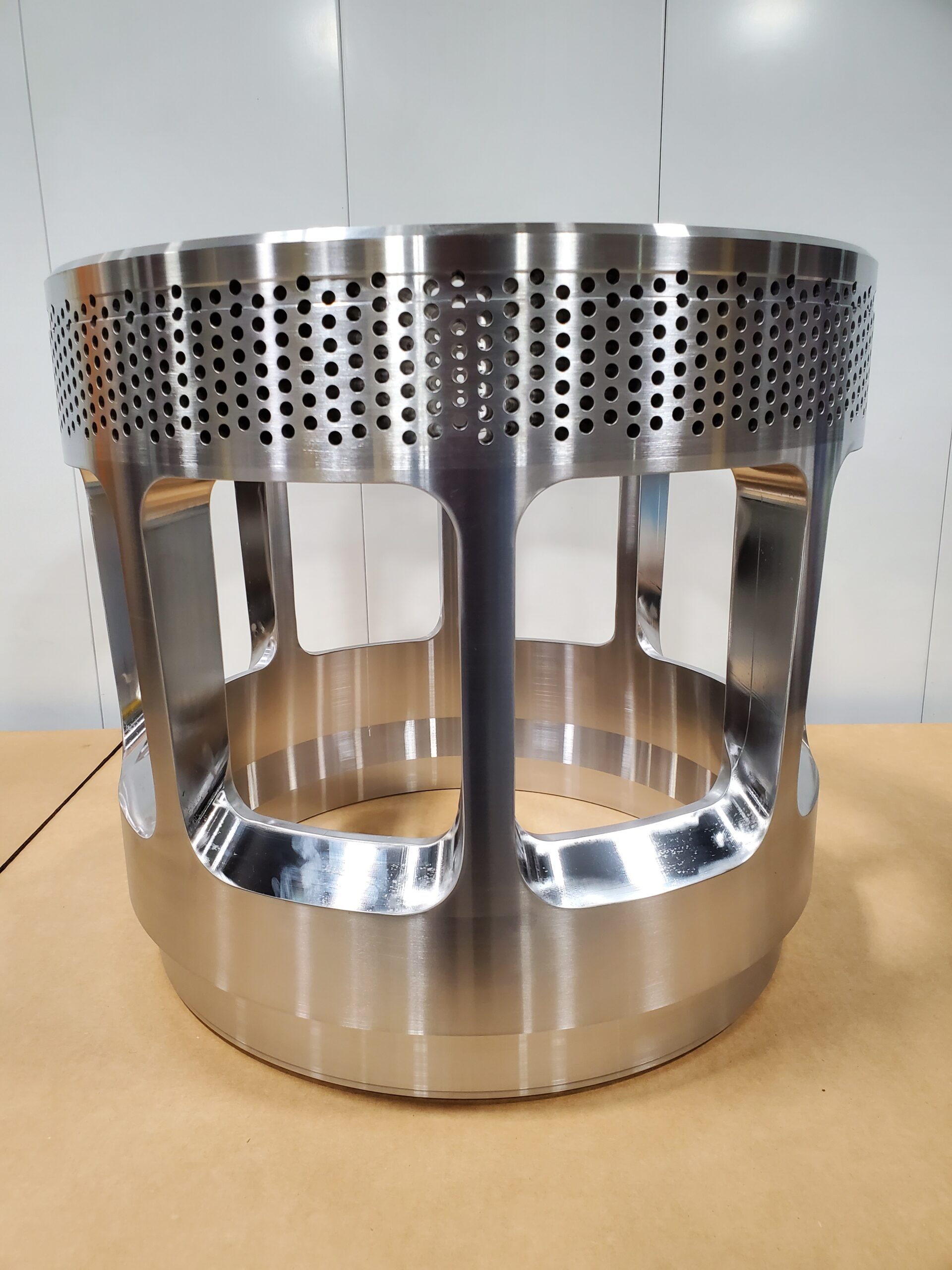

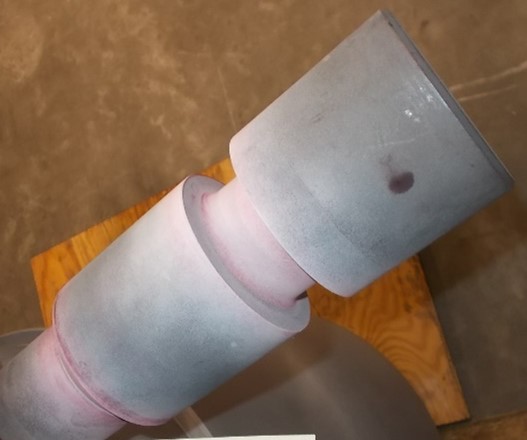

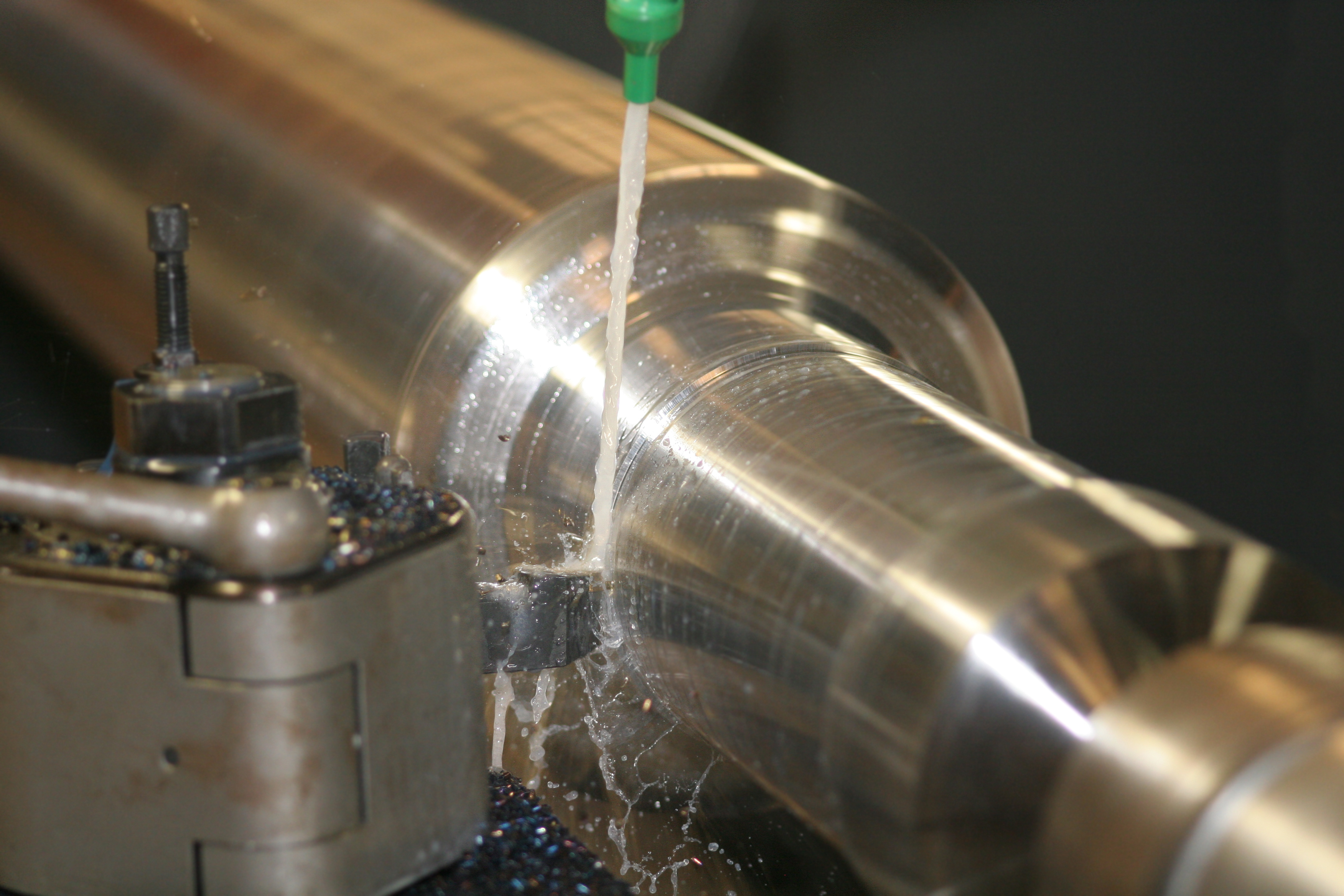

At PSG we meet and exceed OEM standards for all turbine valve repairs performed.

Confident in our quality, we provide a full warranty against defects from time of purchase. Every part, component, or accessory we provide is backed by our reputation for getting it right the first time, on time, and at prices you can afford.

The next time your turbine valves need repair, consider using our ISO 9001:2015 certified facility to meet and exceed your repair requirements. Contact us by visiting our website!