Valve Repair

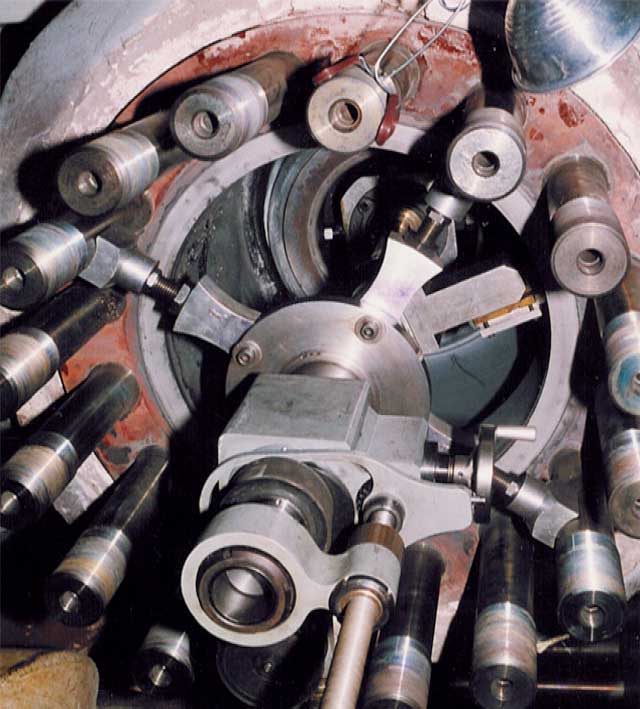

Are you in need of a steam turbine valve upgrade? Power Services Group provides repairs and upgrades for your steam turbine valve components. We maintain one of the industry’s most advanced valve repair equipment inventories, and repair and manufacture all valve components at our ISO 9001:2015 certified facility. We provide reverse engineering and precision replacement part manufacturing of valve components for virtually all types of steam turbine valves.

Please visit our website or call us to learn more.