Combined Cycle Journal provides complete listing of Presenters at 2021 AOG Conference

AOG invites participation by ALL owner/operators in its annual meeting, starting March 1

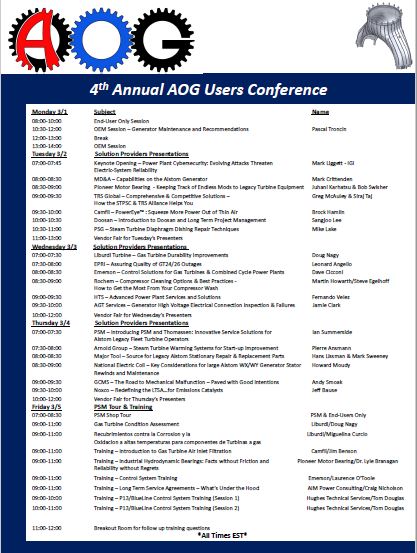

The steering committee for the fourth annual Alstom Owners Group (AOG) Users Conference welcomes participation by all owner/operators of gas and steam turbines in this year’s event, March 1 – 5. The majority of sessions from Tuesday (March 2) to Friday feature content pertaining to most types of turbines (see agenda below).

First step in securing your invitation is to register at www.aogusers.com; this only takes a couple of minutes. There is no registration fee. Questions? Contact conference coordinator Ashley Potts by email.

This year’s conference will be live-streamed globally from PSM’s headquarters in Jupiter, Fla. This location facilitates a virtual tour of PSM’s 105,000-ft² workshop and repair facility, complete with demonstrations at work stations of interest to owner/operators—including blade and vane repairs, additive manufacturing, flow testing, brazing of cobalt and nickel alloys, welding, and machining.

Conference agenda

Monday, March 1. The meeting opens at 8 a.m. (Eastern) with a two-hour user-only session focusing on the repair, service, and maintenance of GT8, GT11, GT13, and GT24/26 engines, with the underlying goal of increasing reliability and controlling costs. The program features formal presentation on the liberation of a GT26 high-pressure compressor blade and instrument failures between C cycles, followed by open discussion.

2021 AOG Steering Committee

- Brian Vokal, Midland Cogeneration Venture

- Robert Bell, Tenaska Berkshire Power

- Chris Hutson, Southern Company

- Pierre Ansmann, Arnold Group

- Jeff Chapin, Liburdi Turbine Services

Discussion topics submitted by users include the following at this time:

-

- Recommendations related to the installation and operation of dehumidification systems, plus lessons learned.

- Experience in the 11N1 fleet with the hardwired pressure switch for starting the emergency dc lube-oil pump. User seeking guidance says he is not getting sufficient pressure drop across the manifold while simulating this low-pressure event to perform an emergency dc lube-oil function test.

- Rotor life management—repair or replace?

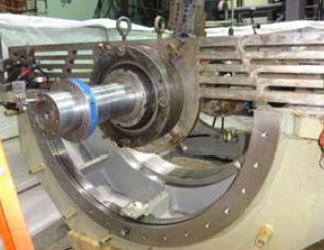

- Operating experience with replacement rotors manufactured by a third party (photo).

- Sharing of experiences with third-party vendors, especially in component repair (delivery issues, lag time, lack of availability, etc).

- Review of recent Technical Information Letters and other OEM notifications.

- Inspection methodology.

- Maintenance challenges.

- Inspection experiences (bearings, SB burners, EV combustor, etc).

- Re-commissioning challenges—cold and hot.

OEM participation following the user discussion session includes a formal presentation on generator maintenance and recommendations followed by Q&A.

Tuesday, March 2. A keynote presentation on cybersecurity by Mark Liggett of IGI kicks off the day at 7 a.m. Eastern. The topic: Evolving attacks threaten electric-system reliability. MD&A follows at 8 with a 30-min presentation of its generator capabilities. Half-hour sessions hosted by Pioneer Motor Bearing, TRS Global, Camfil, Doosan, and Power Services Group (PSG) follow. A vendor fair for the day’s presenters from 11 to 1 p.m. closes out the Tuesday program.

Wednesday, March 3. Presentations by solutions providers begin at 7 a.m. and conclude at 10, when the two-hour vendor fair for Wednesday presenters begins. The lineup of 30-min presentations: Liburdi Turbine, EPRI, Emerson, Rochem, Hughes Technical Services, and AGTServices.

Thursday, March 4 features the same program arrangement as Wednesday, with the following companies participating: PSM, Arnold Group, Major Tool and Machine, National Electric Coil, GCMS, and Noxco.

Friday, March 5, training day, begins at 7 a.m. with a 90-min shop tour of PSM’s facilities. Six concurrent two-hour training sessions follow. The hosts are Liburdi on gas-turbine condition assessment, Camfil on GT inlet filtration, Pioneer Motor Bearing on bearings, Emerson on control systems, AIM Power Consulting on long-term service agreements, and Hughes Technical Services on P13/blueline control system training.

Access www.aogusers.com for program updates and other announcements.