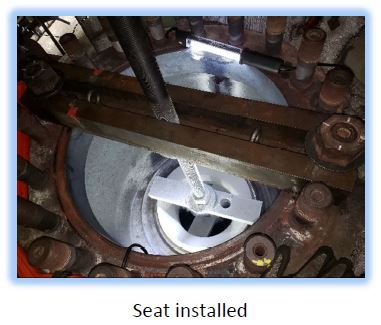

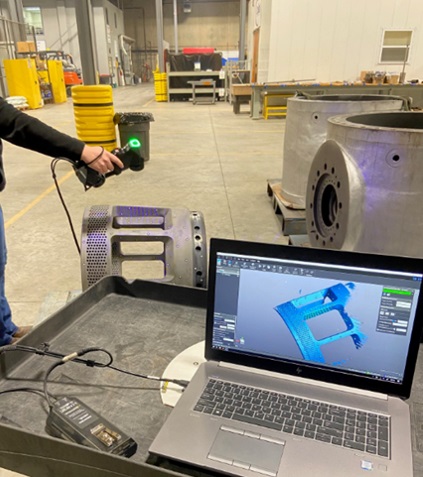

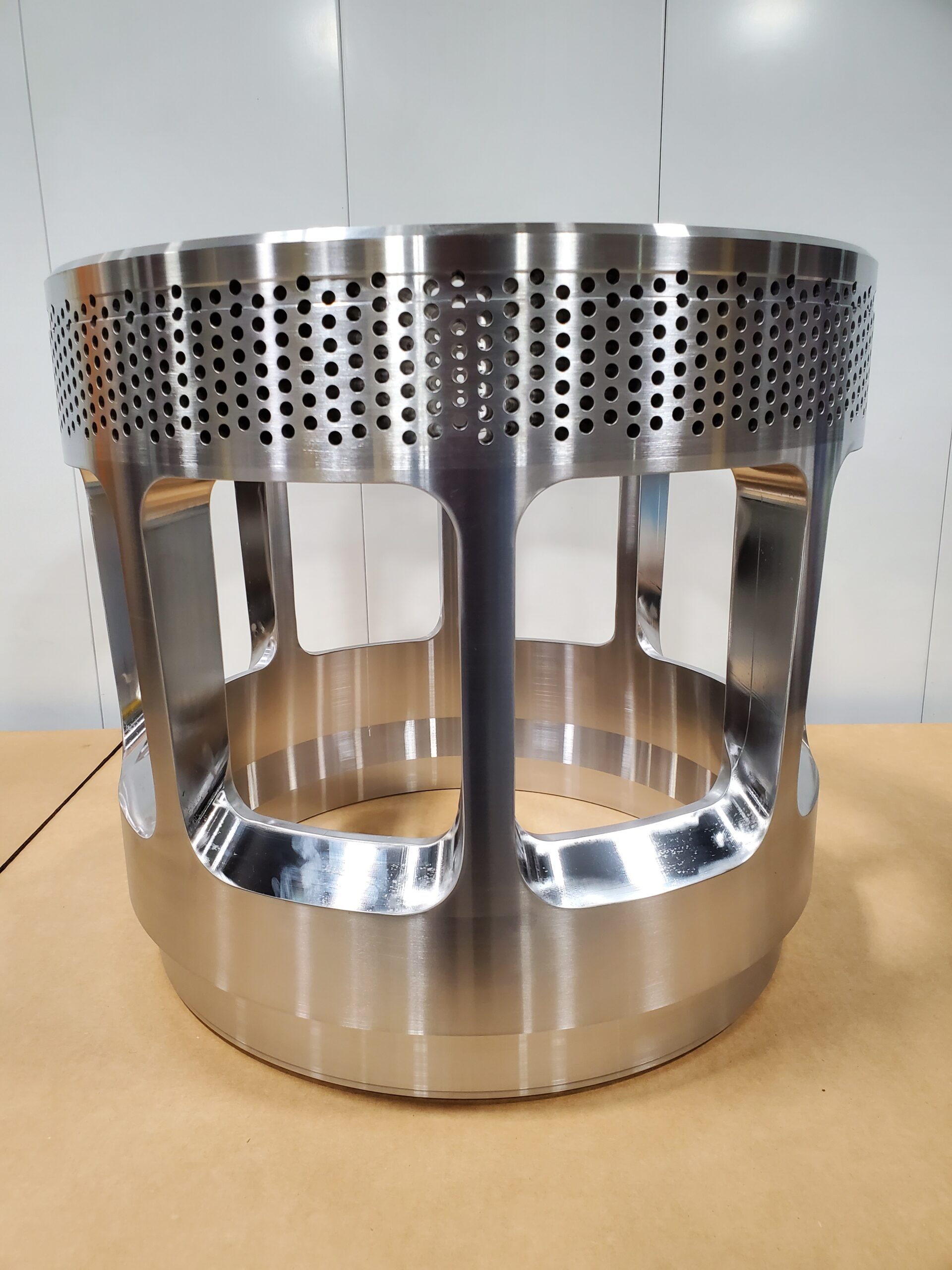

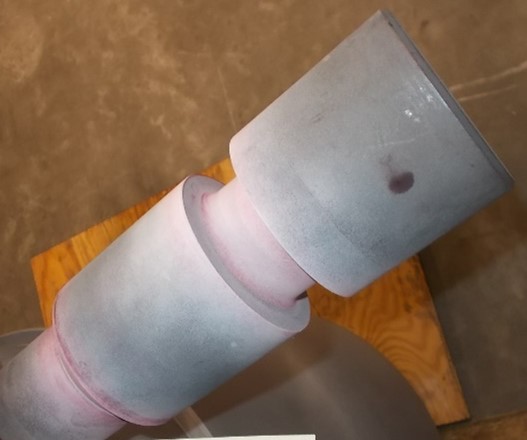

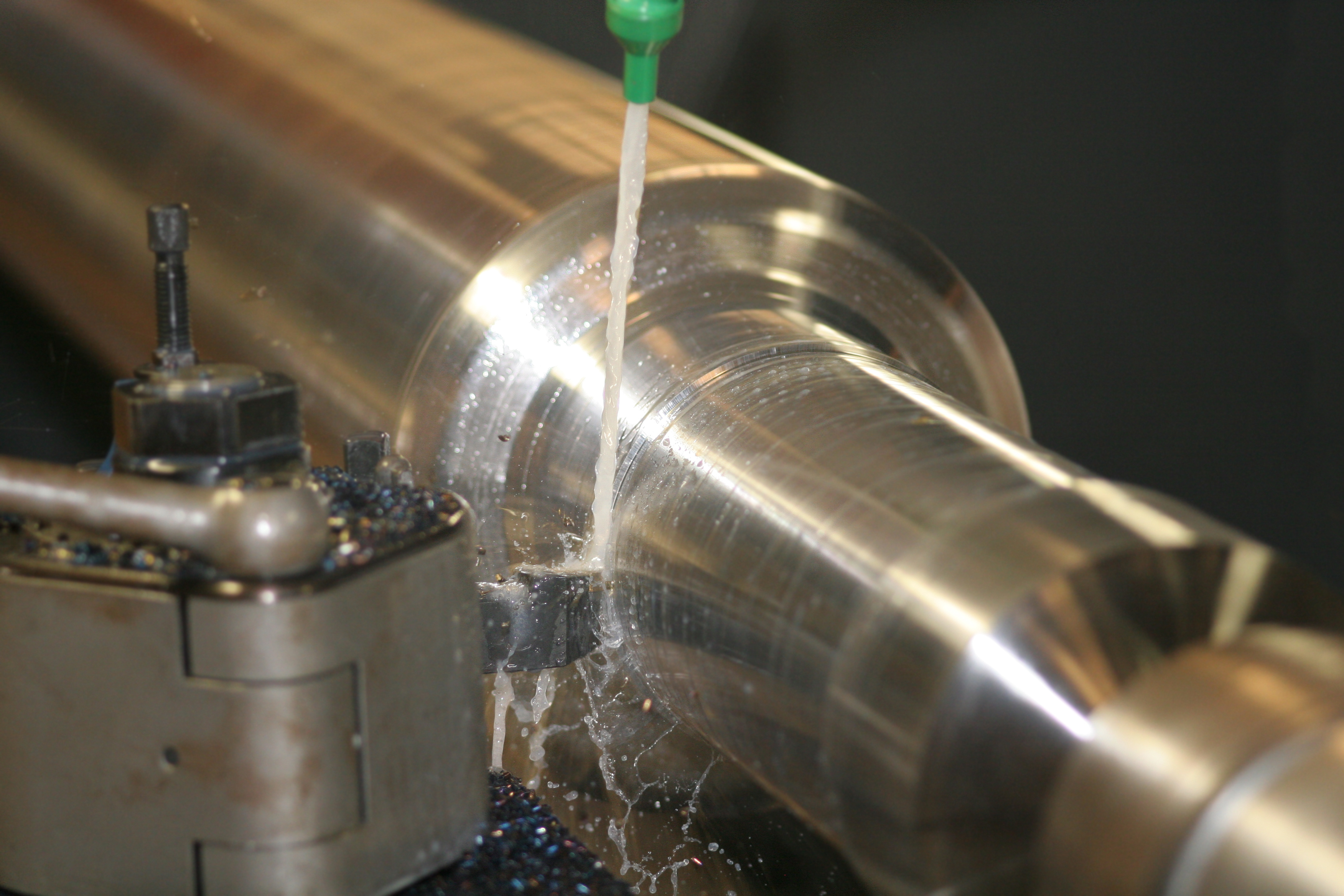

We recently completed a Valve Seat Replacement on a GE Steam Turbine. In some cases the existing seat can be pulled, in the case shown below it was required to machine out the previous seat. We perform many turbine valve seat replacements in the field, and can manufacture the components required at our Gainesville, Georgia Steam Turbine Valve facility. This type of job requires specialty equipment, as well as highly skilled technicians. It is a great example of the high quality craftsmanship that our customers have come to expect from all of our valve machining and component manufacturing services.

If you have any future valve seat replacement projects that you would like us to quote, please CLICK HERE to contact us.