Field Machining

Working on another field machining project in the Midwest, United States.

If you need field machining services, contact Power Services Group today!

Please visit our website for more information.

Working on another field machining project in the Midwest, United States.

If you need field machining services, contact Power Services Group today!

Please visit our website for more information.

Almost finished with another Major Inspection.

Exciter has been reassembled, we’re getting closer…

We received another drive turbine rotor at our Pevely, Missouri Steam Path Repair Facility for incoming inspection.

If you have any turbine inspection needs, please contact us today to see how we can help.

Our very own Mr. Turbine stayed the night in a farmhouse in England that dates back to 1066. The residence was owned over the years by King John and Kings Henry II and III as a hunting lodge.

PSG mobilized tooling, supervision, and craft labor to a paper mill located on the East Coast, USA to perform a scheduled major inspection on their GE steam turbine. The scope of work including removing the steam turbine rotor and steam path components for inspection. The steam turbine rotor and internal components were shipped off site for sand blasting, nondestructive examination (NDE), and inspection. The T-1, T-2, T-3, and T-4 bearings were all sent out for repair. The #1 inboard, #2 inboard, and #3 outboard bearing oil deflectors were sent out for refurbishment, inspections found that all three seals had excessive clearance.

Auxiliary work included: inspecting the NRV valve, 1200# MSV, 850# MSCV, all three lube oil pumps, V-1 upper, V-1 lower, and V-2 valve racks and operating cylinders, the lube oil coolers and generator coolers were shipped out for cleaning and inspections, the lube oil and EHC systems were cleaned utilizing a high velocity oil flush. The generator stator and rotor were inspected and cleaned.

The end result was a successful inspection, with zero safety incidents, and a satisfied customer. If you would like us to quote your next steam turbine major inspection, please click here to submit your request.

|

|

|

We’ve completed the month of September with zero OSHA-recordable injuries and have a TRIR of 0.00 for the year. We continue to be proactive in identifying potential hazards and maintaining our safety-first mindset. Great job by our HSE Director, Shannon Scruggs, our Repair Facility Management and Repair Technicians, and each one of our Field Service Project Management teams and Turbine Mechanics for engraining our safety culture throughout the organization. Nice job everybody!

Outage Season is in full swing! If you are in need of any rotor inspections or repairs please contact us today.

Stop by and visit our 50,000 Sq. Ft. Steam Turbine Valve Repair & Part Manufacturing Facility in Gainesville, Georgia.

It’s that time of year again… Steam Turbines all across the country are opening up right now. Please contact us today to quote any emergent diaphragm repairs that may be required during your steam turbine inspection. We can quote by reviewing photos, or having someone visit the site. We will turn around the quote quickly, allowing you to make a decision and minimize your outage duration. We have a fleet of diaphragm repair technicians that can perform repairs on-site or at our steam path repair facility in Pevely, Missouri. Give us a call to see if we can be the affordable, quality service provider for your diaphragm repairs.

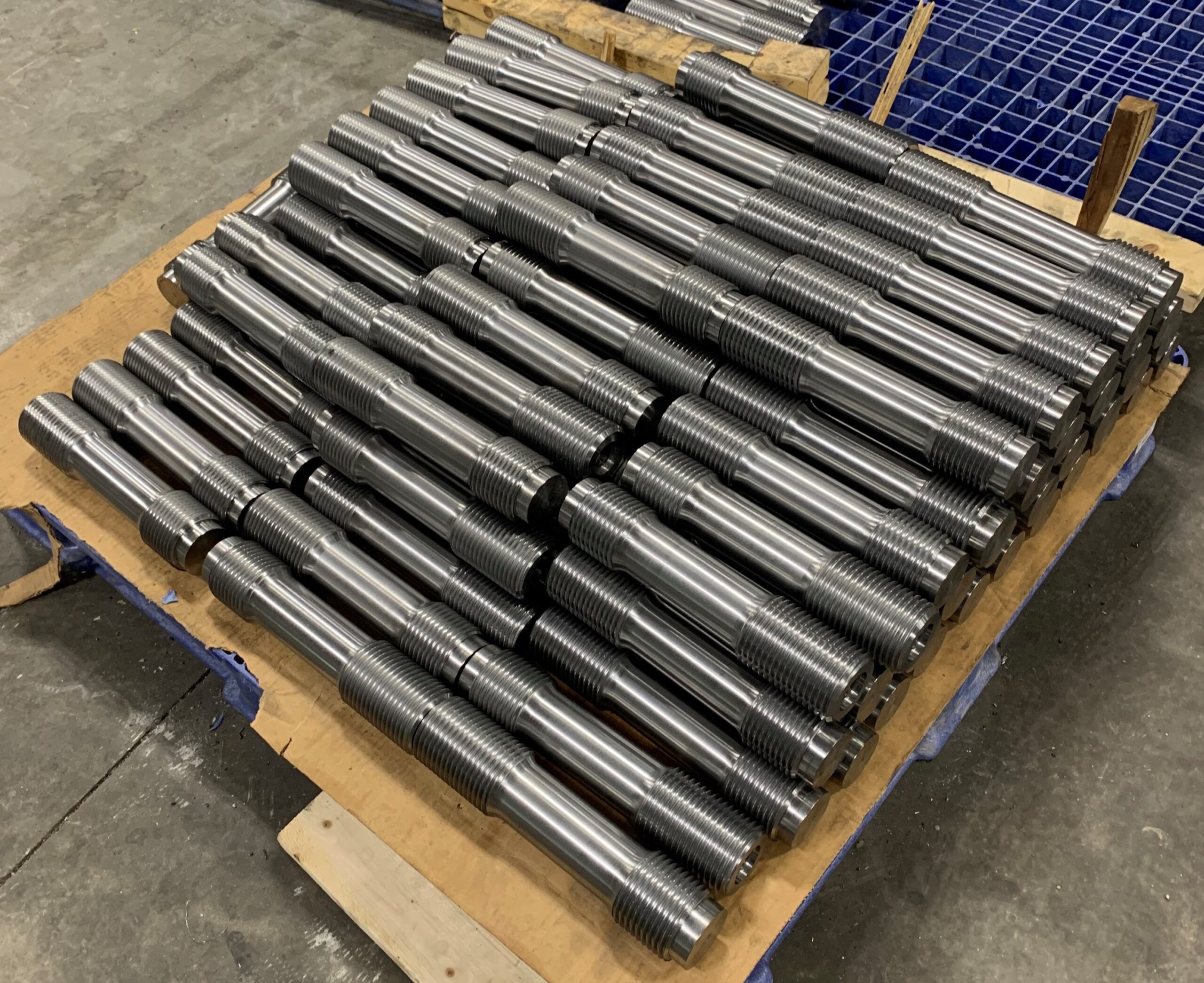

Contact us for all of your steam turbine stud and nut manufacturing needs. For more than a decade, Orbital Energy Services has specialized in design and manufacture of parts in a variety of industries and applications. Our 100% guaranteed aftermarket parts have saved customers substantial amounts of money—money which translates immediately to the bottom line in the form of reduced operating and/or capital expenses.

Our ISO 9001:2015 certified facility is ready and able to assist in the manufacture of your steam turbine components. Reach out to us today to see how we can help you with your next steam turbine parts purchase.

Power Services Group brings you a wide range of services specific to industries like yours, offering exceptional value and responsiveness. We can hit the ground running and deliver results so you can have peace of mind and your equipment is always available.

125 SW 3rd Place, Suite 300

Cape Coral, FL 33991

Phone: (800) 226-7557